Project Description

Fuel Cell Manufacturers

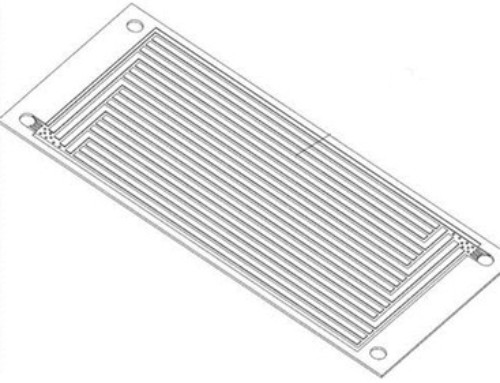

The design and processing technology of metal bipolar plates are mainly controlled by foreign companies. Domestic companies are still in the small-scale development stage. However, Tomorrow Hydrogen Technology Company is building an automated production line with an annual output of 10,000 units. In terms of membrane electrodes, represented by Xinyuan Power and Wuhan Polytechnic New Energy, it initially has production lines of varying degrees, with an annual production capacity of thousands of square meters to 10,000 square meters. However, it is necessary to develop large-scale slit coatings as the representative. Mass production technology. The main manufacturers of perfluorosulfonic acid membranes in the market mainly come from the United States, Japan, Canada and China. my country already has the ability to localize proton exchange membranes. Shandong Dongyue Group’s proton exchange membranes have outstanding performance and large-scale production capacity. At present, the film thickness of Dongyue DF260 can reach 15 μm, and the durability is greater than 600 hours under OCV.

In terms of catalysts, overseas companies are leading, and domestic companies are taking off. There are two types of domestic units that are still in the research stage: domestic companies, such as Guiyan Platinum. Guiyan Platinum is the owner of automotive exhaust platinum catalysts, and it has jointly developed fuel cell catalysts with SAIC Motor. Research institutions, such as Dalian Institute of Chemical Physics, Chinese Academy of Sciences, Shanghai Jiaotong University, Tsinghua University, etc. For example, the Pt3Pd/C alloy catalyst prepared by the Dalian Institute of Chemical Physics, Chinese Academy of Sciences has been applied to fuel cell engines produced by Xinyuan Power.

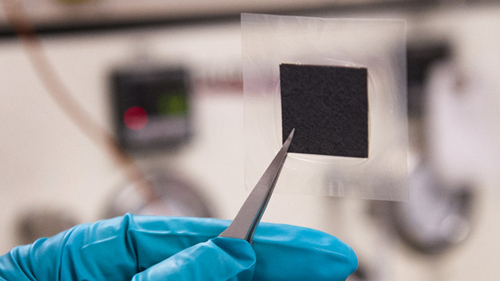

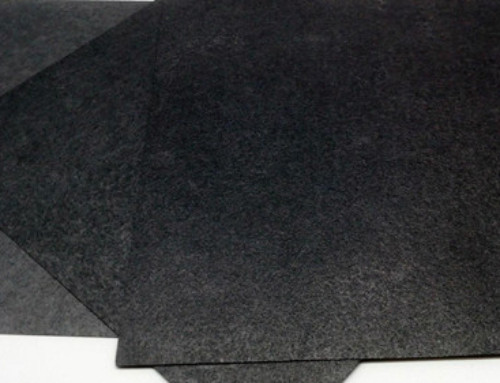

In terms of carbon paper products, it is mainly monopolized by several major international manufacturers such as Japan Toray Company. Domestic carbon paper products are still in the stage of research and development and small-scale production. In terms of system components, hydrogen circulation pumps mainly rely on imports, and air compressors have not yet been able to mass-produce, and there is a lack of low-power, high-speed, oil-free air compressor products.

All in all, my country has a layout in terms of complete vehicles, systems, and stacks, but there are still few related companies in terms of parts, especially the most basic key materials and components, such as proton exchange membranes, carbon paper, catalysts, and air. Compressors, hydrogen circulation pumps, etc. Although relevant domestic companies have begun to intervene, there is still a big gap in reliability and durability compared with international advanced products. Most key components and key materials still rely on imports.

Ultrasonic Fuel Cell Coating Video

Recommended Machine

UAL100 ultrasonic dispersion liquid supply system

UAM3000 Ultrasonic Bracket Spraying Machine

UAM4000 small desktop ultrasonic spraying machine

UAM4000L Ultrasonic Precision Spraying Machine

UAM6000 Ultrasonic Large Spraying Machine

UAM7000 Ultrasonic Balloon Guide Wire Spraying Machine

UAM8000 ultrasonic assembly line spraying machine