Project Description

Do you know about ultrasonic sewing machines?

Do you know about ultrasonic sewing machines – Cheersonic

Ultrasonic sewing technology is widely used in the textile and apparel industry. After the ultrasonic sewing machine is reopened for cutting and sealing operations, the connecting lines of the fabric board are almost invisible, and the seam will not be thicker than the fabric itself. This advantage is unmatched by traditional sewing machines. .

Textile materials suitable for ultrasonic technology

Materials suitable for ultrasonic processing include 100% synthetic fibers, such as nylon, polyester, polypropylene, certain polyethylene, modified acrylic resins, certain vinyl compounds, urethane compounds, films, coated paper, etc. . It also includes synthetic fibers mixed with 35-50% non-synthetic fiber components.

Advantages of ultrasonic application in textile industry

1. Fast, economical and high stitching strength

2. No need to use auxiliary materials (such as: nails, glue, paper clips, etc.)

3. Ensure consistent results throughout the production process

4. No time-consuming warm-up and recovery, and no expensive cost to maintain the temperature

5. Independent cutting and stitching, no burrs

6. No pollution, avoid the use of toxic viscose and solvent

7. There are no needle holes in the seam, which can prevent the penetration of chemical agents, pathogens and tiny harmful particles

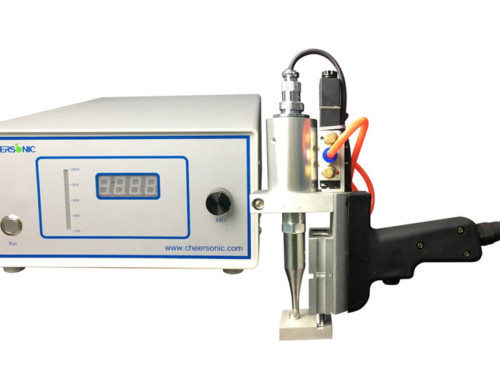

Conventional ultrasonic processing technology

(1) Ultrasonic heat sealing or “sewing”:

This process can be used to form continuous seams, such as the production of protective clothing, blinds, etc., or to process immersion welding similar to buttonholes, collar stays, ties, etc. Stand-alone “sewing” equipment or standard ultrasonic welding machines can realize this process.

(2) Rotary drum welding and lamination:

Developed the application of ultrasonic rotating drum to the bonding and lamination process of multiple wide mesh woven or non-woven synthetic fiber materials. The process is to pass multiple layers of fiber material in a rotating printing cylinder and a row of welding heads to form a network pattern of sufficient width. This method does not require any chemical adhesives and other auxiliary materials to be processed into unique fabrics that other bonding methods cannot achieve. Bed covers, mattresses, disposable medical supplies, etc. can all be processed in this way.

(3) Ultrasonic cutting:

Compared with other methods, ultrasonic cutting can form smooth, long-lasting, neat edges, and will not cause discoloration of the fabric. Ultrasonic can cut and seam at the same time, which prevents the knitted or textile materials from forming thread off. At the same time, the seam has a taper to avoid pilling. Applications of ultrasonic cutting include cutting carpets, strips, clothing labels, curtains, diagonal cuts and industrial woven tapes.