Project Description

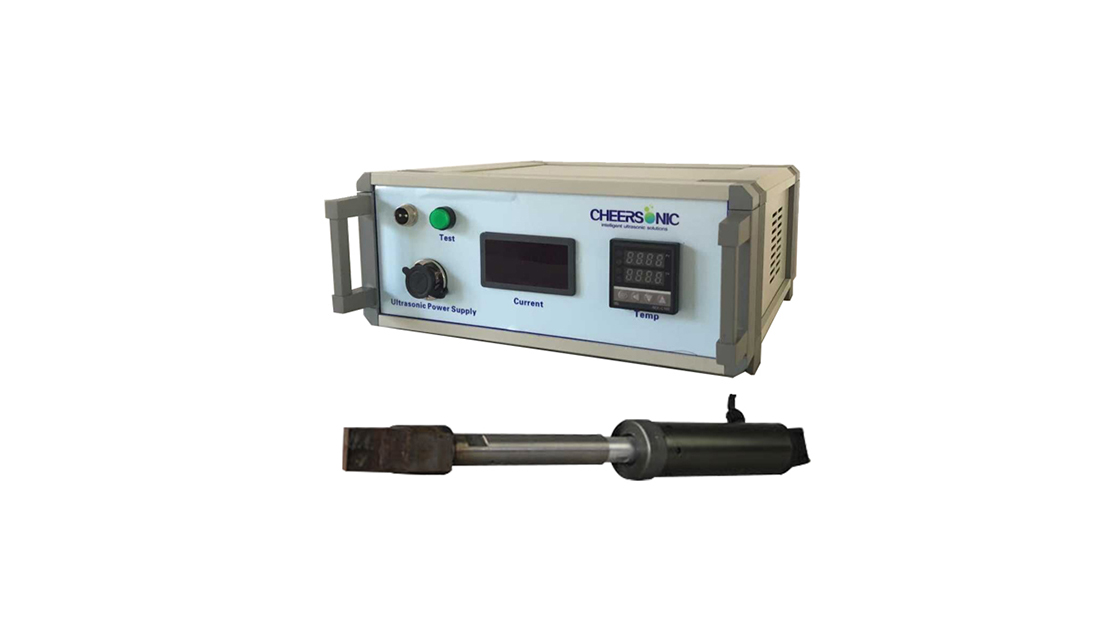

CS28-X70I ULTRASONIC SOLDERING IRONS

Ultrasonic Soldering Irons are mainly used for “flux-less soldering” or “fulx free” to non metals such as glass, ceramic, and to such difficult-to-solder metals as aluminum and stainless steel. Ultrasonic soldering help manufacturers to reduce or eliminate the use of halogen material, which is the main chemical of flux.

In an ultrasonic soldering system, soldering is done with a heated soldering tip that also simultaneously emits ultrasonic vibrations. The ultrasonic waves generated from oscillator are transferred to the soldering tip via a horn, producing cavitation bubbles at the interface between the substrate and the molten solder. The implosive energy of cavitation changes the oxide surface and removes dirt and the oxide layer. At the same time, an alloy layer is formed though melting and spreading action.

APPLICABLE INDUSTRIES

ENERGY

- FUEL CELL

- THIN FILM SOLAR CELL

- SILICON SOLAR CELL

ELECTRONICS

- SPRAY FLUX

- SEMICONDUCTOR

- TOUCH SCREEN

Features

• ECO friendly soldering solution: Flux and flux-cleaning process are not needed.

• Perfect Soldering: No Flux Soldering, highly Solid and Reliable Soldering Joint

• Production Cost Savings & High Productivity

• Support of New Application Development: Applying to Solar Cell Glass, Semiconductor, Ceramic Heater, Soldering of Dissimilar Materials (Al-Cu, Al-Glass, Al-Ceramic)

Basic Specifications

• Frequency: 28KHz±5KHz

• Output power: 70 Watt

• Power: AC100V / 240V,50 / 60Hz,200W

• Operation panel: working temperature, power adjust switch

• Max temperature: 350℃

• Display: amplitude, power, set temperature, current temperature