Project Description

Coated Catalyst Layer

The catalyst layer is the place where the hydrogen and oxygen in the hydrogen fuel cell electrochemically react to generate electricity, which can be said to be the core of the hydrogen fuel cell. Since there are three components participating in the chemical reaction, namely gas (hydrogen and oxygen), electrons and protons, it is required that the above three components can reach the surface of the catalyst. The gas passes through the voids, the electrons pass through the conductive carrier, and the protons pass through the ionomer, which places high demands on the catalyst layer material. Firstly, it must be porous so that hydrogen and oxygen can pass through; secondly, its conductivity must be good, so that the current can be large; secondly, it has good contact with the ionomer to ensure that protons can pass through; thirdly, the catalyst layer must be very thin , Minimizing the potential loss of the battery caused by the proton migration rate and the penetration of the reaction gas into the catalyst layer; finally, the water generated by the reaction must be effectively removed, otherwise the catalyst will be immersed in the water and the gas cannot be reached.

How to prepare high-quality fuel cell catalytic layer?

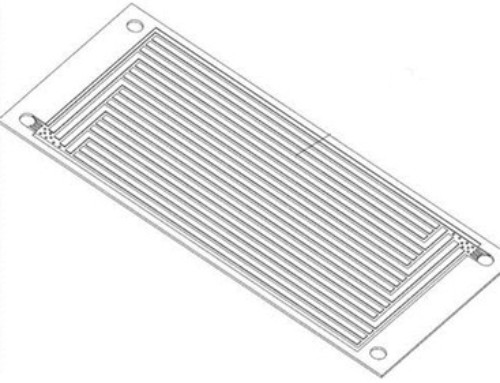

Ultrasonic coating technology creates highly uniform, repeatable and durable membrane. It operates through continues vibration from the nozzle to break up the agglomerated particles into evenly dispersed functional particles, maximizing surface area exposure of the catalyst to create higher electrochemical performance of coatings. And when using the ultrasonic spray coating technology apply catalyst coating to the membranes by adjusting the spray parameters (height, flow rate and frequency of the nozzle) to control the rate of water added, because it needs to keep the thin membrane moist and not deformed.

Cheersonic has committed to the research and development of various ultrasonic equipment for more than ten years. UAM4000L, UAM6000 and UAM8000 developed by our company is basic , programmable micro material spray coating system. Various types of catalysts suspensions including the carbon black ink , PTFE binder, ceramic slurry, platinum and other precious metal can be sprayed by using this bench-top ultrasonic spraying system capable of programming and controlling x, y, z three-axis coordinated operation are deposited onto PEM fuel cells, GDL, electrodes, electrolyte membranes and SOFC to create maximum load and high cell efficiency. Precise and controllable liquid supply system compared with different types of customized nozzles, significant reduction in materials usage and producing the highly uniform durable, repeatable and durable coatings from R & D to medium-sized batch production. The body is small and easy to place, the spraying performance is stable, and the operation is convenient.