Project Description

Catalyst Coating Deposition

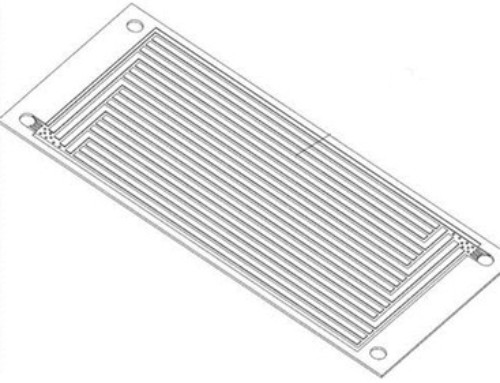

As we all know, the core system of a fuel cell is an electric stack, which is the decisive factor of the fuel cell industry chain. As an indispensable raw material, the catalyst is one of the key materials of the membrane electrode (MEA) of the proton exchange membrane fuel cell. It determines

How to prepare high-quality spray fuel cell catalysts?

Ultrasonic coating technology creates highly uniform, repeatable and durable membrane. It operates through continues vibration from the nozzle to break up the agglomerated particles into evenly dispersed functional particles, maximizing surface area exposure of the catalyst to create higher electrochemical performance of coatings. And when using the ultrasonic spray coating technology apply catalyst coating to the membranes by adjusting the spray parameters (height, flow rate and frequency of the nozzle) to control the rate of water added, because it needs to keep the thin membrane moist and not deformed.

Cheersonic has committed to the research and development of various ultrasonic equipment for more than ten years. UAM4000L, UAM6000 and UAM8000 developed by our company is basic , programmable micro material spray coating system. Various types of catalysts suspensions including the carbon black ink , PTFE binder, ceramic slurry, platinum and other precious metal can be sprayed by using this bench-top ultrasonic spraying system capable of programming and controlling x, y, z three-axis coordinated operation are deposited onto PEM fuel cells, GDL, electrodes, electrolyte membranes and SOFC to create maximum load and high cell efficiency. Precise and controllable liquid supply system compared with different types of customized nozzles, significant reduction in materials usage and producing the highly uniform durable, repeatable and durable coatings from R & D to medium-sized batch production. The body is small and easy to place, the spraying performance is stable, and the operation is convenient.