Optical Lens Coating

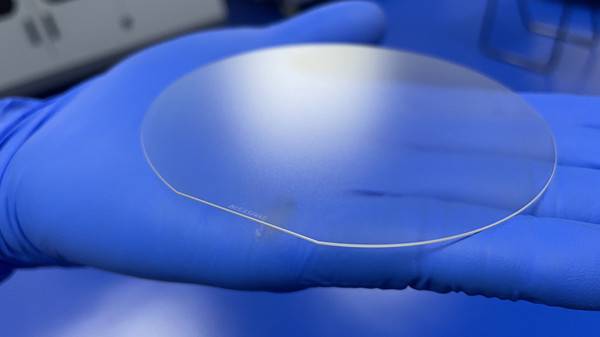

Optical lens coating using ultrasonic spray systems is an advanced technique that offers numerous advantages over traditional coating methods such as dipping and spin coating. Ultrasonic spray systems are well-suited for applying functional and aesthetic coatings to eyeglass lenses and other optical surfaces due to their ability to deliver precise, thin film coatings with minimal overspray.

One of the key benefits of ultrasonic lens coating systems is their precision. By using ultrasonic energy to atomize the coating solution and spray it onto the lens surface, these systems are able to achieve a high degree of control over the coating thickness and uniformity. This is particularly important for optical coatings, where even small variations in thickness can impact the performance of the lens.

Another advantage of ultrasonic spray systems is their minimal overspray. Overspray refers to the unintended deposition of coating material onto areas other than the intended target. With traditional coating methods like dipping and spin coating, it can be difficult to avoid overspray, leading to waste of expensive coating solutions and the need for additional cleaning steps. Ultrasonic spray systems, on the other hand, are designed to deliver the coating solution in a highly targeted manner, minimizing overspray and reducing waste.

Ultrasonic lens coating systems are also well-suited for applying coatings with high viscosities, which can be challenging to apply using other methods. The ultrasonic energy used in these systems helps to break down the coating solution into smaller droplets, making it easier to spray onto the lens surface and achieve a smooth, even coating.

In addition to their precision and minimal overspray, ultrasonic lens coating systems offer a number of other benefits. They are fast and efficient, allowing for high-throughput production of coated lenses. They are also easy to use and can be easily integrated into existing manufacturing processes.

Overall, ultrasonic lens coating systems are an excellent choice for applying functional and aesthetic coatings to optical surfaces such as eyeglass lenses. Their precision, minimal overspray, and ability to handle high-viscosity coatings make them an ideal solution for manufacturers looking to improve the quality and efficiency of their lens coating processes.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions