Megasonic Cleaning Technology

Megasonic Cleaning Technology – Ultrasonic Cleaning – Cheersonic

Megasonic cleaning is developed from ultrasonic cleaning. It uses a transducer to emit megahertz-level high-energy sound waves (vibration generates 0.8 MHz), and the solution molecules are accelerated by this sound wave (the maximum instantaneous speed reaches 30 cm). /s), a cleaning technology that desorbs the adsorbed fine particles by the continuous impact of the high-speed hydrodynamic layer generated by the strong sound pressure gradient and the sound flow. As a nano-level precision cleaning technology, megasonic cleaning not only inherits the advantages of ultrasonic cleaning, but also overcomes its defects. It has more advantages than ultrasonic cleaning technology in terms of viscous layer thickness, power density, resonance effect, and diffraction effect.

Since ultrasonic cleaning is difficult to remove particles smaller than 1 μm on the surface of semiconductor wafers, megasonic cleaning has less damage to the surface, and can effectively remove particles smaller than 0.2 μm on the surface of the wafer, which can achieve the effect that ultrasonic waves cannot play. The frequency of sonic cleaning technology is too high, it is difficult to produce cavitation effect in the solution, and bubbles like ultrasonic cleaning will not be formed during cleaning. The substance will peel off with the solution. For the high-efficiency and high-precision requirements of wafers, megasonic cleaning technology plays the role of two methods of mechanical cleaning and chemical cleaning at the same time.

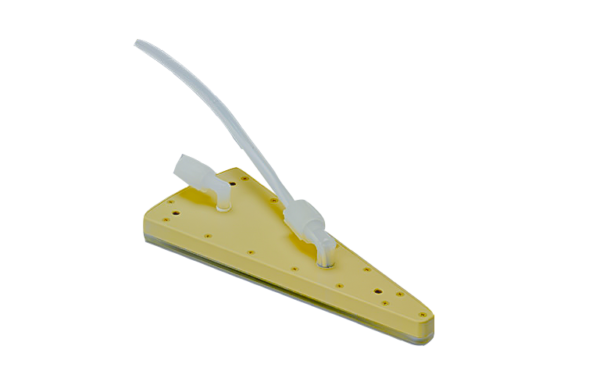

Megasonic cleaning is usually divided into two types: spray type megasonic cleaning and slot type megasonic cleaning. The spray-type megasonic cleaning is to transmit high-frequency ultrasonic waves through the water flow through a high-frequency ultrasonic transducer, and the objects to be cleaned contact the water flow with high-frequency ultrasonic waves to achieve the purpose of cleaning. Compared with traditional tank cleaning, spray megasonic cleaning has higher cleaning efficiency and avoids the problem of secondary pollution of cleaning water residues. The tank-type megasonic cleaning is similar to the traditional ultrasonic cleaning. The high-frequency megasonic cleaning vibrator is located at the bottom of the cleaning tank, forming a high-frequency ultrasonic sound field in the cleaning tank. The advantage of the tank-type megasonic cleaning is that multiple wafers can be cleaned at the same time. Suitable for batch cleaning.