Fuel Cells Coating

Cheersonic ultrasonic nozzles break apart agglomerated particles as they travel down the nozzle body due to continuous ultrasonic vibrations along the length of the nozzle, resulting in the most effective use of functional particles. Breaking up agglomerates into evenly dispersed catalyst layers using ultrasonic spray results in higher electrochemical performance and greater repeatability of functional coatings.

A variety of fuel cells utilize catalysts at both the anode (to oxidize fuel and convert it to protons/hydrogen cations and electrons) and the cathode (convert hydrogen cations and oxygen to water), often precious metal, nanocarbon, or other nanomaterial-based. Doped carbon nanotubes and core-shell metallic or composite nanoparticles are two examples of such. Such catalyst materials need first to be synthesized and then coated onto electrode and/or membrane surfaces for use in fuel cells. Solid oxide fuel cells (SOFCs) that do not utilize catalyst coatings are also of interest.

Ultrasonic Fuel Cells Coating Video

Recommended Equipment

Ultrasonic Atomization Nozzle

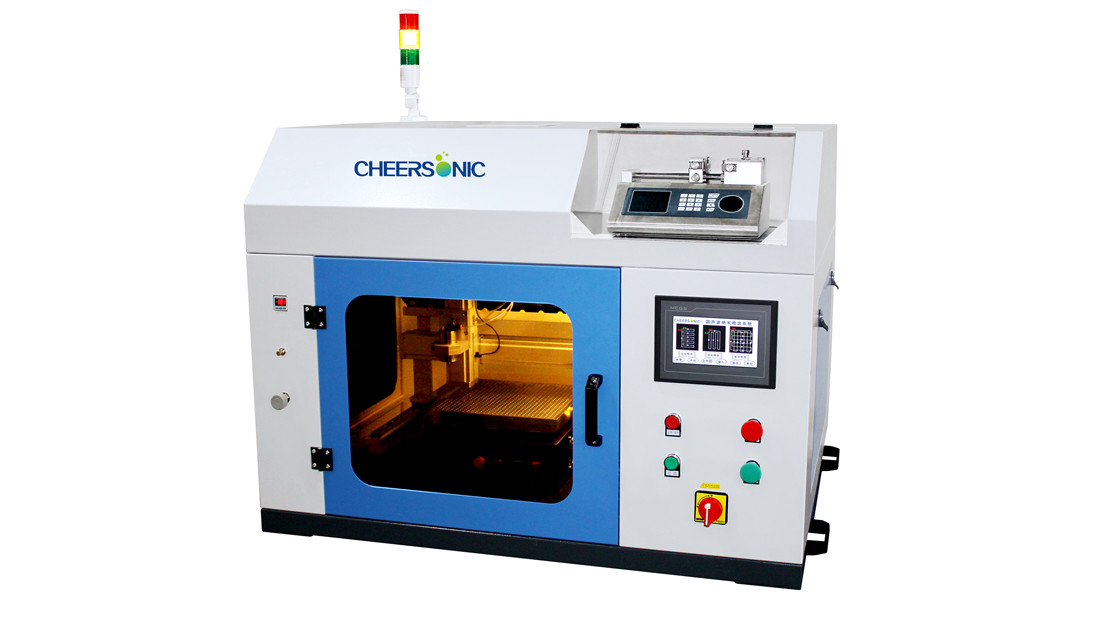

Laboratory Ultrasonic Coating System

UAM3000 Ultrasonic Medical Devices Spraying

UAM4000 Desktop Ultrasonic Spraying Equipment

UAM4000L Benchtop Ultrasonic Spray System

UAM6000 Ultrasonic Spraying Machine

UAL100 Ultrasonic Dispersion Syringe Pump

LULP500 Ultrasonic Laboratory Device

Prosonic1000 Industrial Ultrasonic Device

Prosonic3000 Most Powerful Ultrasonic Processor