Fuel Cell Proton Exchange Membrane

Proton exchange membrane (PEM) fuel cell Proton exchange membrane is one of the most advanced fuel cell designs. Hydrogen under pressure is forced through a catalyst usually made of platinum into the anode (negative) side of the fuel cell. On this catalyst, electrons are stripped from the hydrogen atoms and carried to the cathode (positive) side by an external circuit. The positively charged hydrogen ions (protons) then pass through the proton exchange membrane to the catalyst on the cathode side, where they react with oxygen and electrons from the circuit to form water vapor (H 2 O) and heat. The circuit is used to complete work, such as powering a motor.

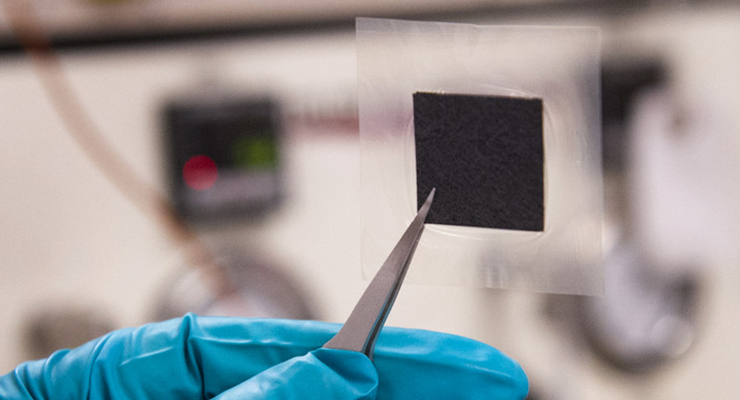

Ultrasonic coating systems can produce highly durable and uniform carbon-based catalyst ink coatings on the electrolysis process of fuel cells and proton exchange membrane (PEM) electrolyzers (such as Nafion) without deforming the membrane. The uniform catalyst coating is deposited on PEM fuel cells, GDL, electrodes, various electrolyte membranes and solid oxide fuel cells with suspension. The suspension contains carbon black ink, PTFE binder, ceramic slurry, platinum and Other precious metals. The ultrasonic coating system can coat PEM with very small liquid sample size (only need to coat 10ml catalyst solution to coat multiple PEMs). Ideal for the development stage. Excellent adherence to PEM; “Persistence”; most suitable for high vibration fuel cell applications, such as automotive parts.

Ultrasonic Fuel Cell Coating Video

Recommended Machine

UAL100 ultrasonic dispersion liquid supply system

UAM3000 Ultrasonic Bracket Spraying Machine

UAM4000 small desktop ultrasonic spraying machine

UAM4000L Ultrasonic Precision Spraying Machine

UAM6000 Ultrasonic Large Spraying Machine

UAM7000 Ultrasonic Balloon Guide Wire Spraying Machine

UAM8000 ultrasonic assembly line spraying machine