Fuel Cell Catalyst Coating

Fuel cell working principle

Although the name “fuel” is included in the fuel cell name, and hydrogen can also burn with oxygen violently, fuel cells do not use combustion to obtain energy, but use the charge transfer in the chemical reaction between hydrogen and oxygen to form an electric current. The most critical technology in this process is the use of a special “electrolyte film” to split hydrogen. The entire process can be understood as mosquitoes cannot pass through the screen window, but smaller dust can … Electrolyte film is also the most difficult in the field of fuel cells Overcoming technical barriers.

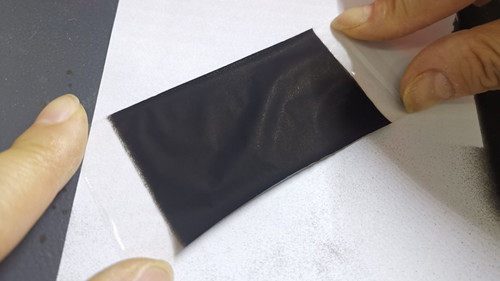

Ultrasonic spray deposition for production of fuel cells electrolyte film

Compared with conventional coating technology, fuel cell carbon catalyst ink films made with ultrasonic nozzles have several key advantages: the largest surface area of platinum exposed and uniformly dispersed particles, the largest film thickness uniformity, and the platinum mesh density to produce the most A large amount of platinum can be used for airflows where there are no inconsistent hot spots or low catalyst density areas, and the film characteristics have maximum repeatability without degrading process performance. The platinum film deposited by the Cheersonic ultrasonic spraying method has an efficiency of more than 90% to optimize the coating efficiency, and the repeatability is ± 1%.

Fuel Cell Catalyst Coating Systems Video

Recommended Equipment

Ultrasonic Atomization Nozzle

Laboratory Ultrasonic Coating System

UAM3000 Ultrasonic Medical Devices Spraying

UAM4000 Desktop Ultrasonic Spraying Equipment

UAM4000L Benchtop Ultrasonic Spray System

UAM6000 Ultrasonic Spraying Machine

UAL100 Ultrasonic Dispersion Syringe Pump

LULP500 Ultrasonic Laboratory Device

Prosonic1000 Industrial Ultrasonic Device

Prosonic3000 Most Powerful Ultrasonic Processor