EMI Shielding for Spray Coating

Wearable device technology and other types of wireless devices rely on different radio frequencies, which may interfere with each other, resulting in unnecessary electromagnetic interference (EMI). Historically, “metal cans” or “lids” have been used to make partial Faraday cages to protect sensitive components from interference. As manufacturers continue to design thinner and smaller devices, the development of new, reliable EMI shielding solutions built into the package itself has become increasingly important.

In recent years, various methods have been used to directly apply very thin silver-based coatings to the outside of individual packages or components to form an external EMI shield. For complex system-in-package devices, sometimes internal structures are built into these packages before final packaging of the external EMI shielding coating to create smaller Faraday cages around specific components. At present, ultrasonic spray coating and then low-temperature thermal curing provide a cost-effective alternative to packaging-level EMI (electromagnetic interference) shielding processes, which can replace expensive sputter-based coating equipment.

Advantages

• Greatly reduce the capital equipment investment, with the smallest footprint

• Selectively apply materials around restricted areas and complex geometries, ideal for trench filling applications

• Uniform coverage and thickness of side walls and top surface

• The thickness of the shielding material is in the range of 3-6 µm

• Minimize or eliminate the need for masks

• Reduce material waste

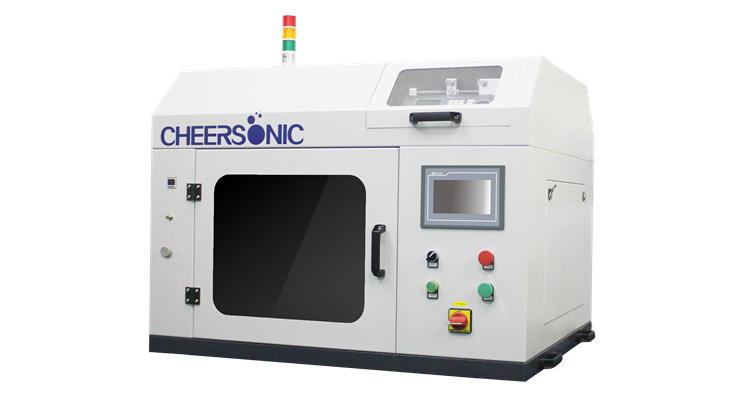

Recommended Machine

UAL100 ultrasonic dispersion liquid supply system

UAM3000 Ultrasonic Bracket Spraying Machine

UAM4000 small desktop ultrasonic spraying machine

UAM4000L Ultrasonic Precision Spraying Machine

UAM6000 Ultrasonic Large Spraying Machine

UAM7000 Ultrasonic Balloon Guide Wire Spraying Machine

UAM8000 ultrasonic assembly line spraying machine