Cost of Hydrogen Production

1. Cost of hydrogen production from fossil fuels:

Hydrogen production from non reduced fossil fuels (mainly through natural gas steam reforming) is currently the cheapest method of hydrogen production, with a global cost range of 0.8 to 5.7 US dollars per kilogram of hydrogen. This hydrogen production method remains competitive in terms of cost, especially in countries where natural gas prices are relatively stable, such as the United States and the Middle East.

2. Cost of hydrogen production through electrolysis of water:

The current cost of hydrogen production through electrolysis of water is relatively high, with a global cost range of 3 to 10 US dollars per kilogram of H ₂, mainly influenced by electricity prices and electrolysis cell efficiency. The cost reduction of electrolytic cell production mainly relies on large-scale manufacturing and technological innovation.

China dominates the global electrolytic cell manufacturing industry, with 60% of the world’s electrolytic cell manufacturing capacity located in China. China is expected to significantly reduce the global cost of hydrogen production through large-scale production and supply chain optimization. It is expected that by 2030, with technological advancements and large-scale deployment, electrolytic cells produced in China can reduce the cost of hydrogen production from electrolyzed water to 2 to 5 US dollars per kilogram of hydrogen.

3. Cost of CCUS fossil fuel hydrogen production:

The use of carbon capture and storage (CCUS) technology for fossil fuel hydrogen production is expanding in North America and Europe. The current cost of this hydrogen production method is approximately 2 to 7 US dollars per kilogram of H ₂, slightly higher than traditional non emission reducing fossil fuel hydrogen production, but with the maturity of technology and policy incentives, it is expected that the cost will further decrease in the future.

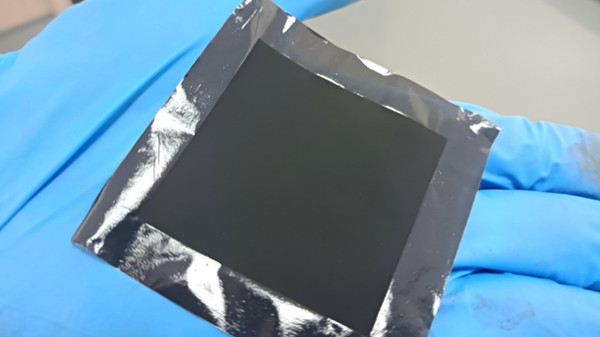

Hydrogen production by electrolysis of water is the most advantageous method for producing hydrogen. Utrasonic coating systems are ideal for spraying carbon-based catalyst inks onto electrolyte membranes used for hydrogen generation. This technology can improve the stability and conversion efficiency of the diaphragm in the electrolytic water hydrogen production device. Cheersonic has extensive expertise coating proton exchange membrane electrolyzers, creating uniform, effective coatings possible for electrolysis applications.

Cheersonic ultrasonic coating systems are used in a number of electrolysis coating applications. The high uniformity of catalyst layers and even dispersion of suspended particles results in very high efficiency electrolyzer coatings, either single or double sided.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions