Compare Traditional Spraying And Ultrasonic Spraying

Compare Traditional Spraying And Ultrasonic Spraying – Cheersonic

Blade coating works as follows. The film substrate passes through the coating roller and directly contacts the slurry tank. The excess slurry is coated on the film substrate. When the substrate passes between the coating roller and the doctor blade, the gap between the doctor blade and the substrate determines the thickness of the coating. At the same time, the excess slurry is scraped back to form a uniform coating on the substrate surface . The main type of scraper is a comma scraper. The comma blade is one of the key components of the coating head. Generally, a comma-shaped blade is formed along the generatrix on the surface of the round roller. The scraper has high strength and hardness, and the coating amount and coating accuracy are easy to control, and it is suitable for muds with high solid content and high viscosity. It can be seen that the disadvantage of the blade coating is that the catalyst coating cannot be too thick, the uniformity is poor, and the uniformity of the substrate thickness is required to be high, which causes the waste of the catalyst solution to a certain extent.

Ultrasonic coating technology creates a highly uniform, repeatable and durable film. Through the continuous vibration of the nozzle, it decomposes the agglomerated particles into uniformly dispersed functional particles, maximizing the surface area of the catalyst, thereby improving the electrochemical performance of the catalyst coating. And when using ultrasonic spraying technology, the catalyst is sprayed onto the membrane by adjusting the spraying parameters (nozzle height, flow rate and frequency) to control the amount of water added, because it needs to keep the membrane moist and not deformed.

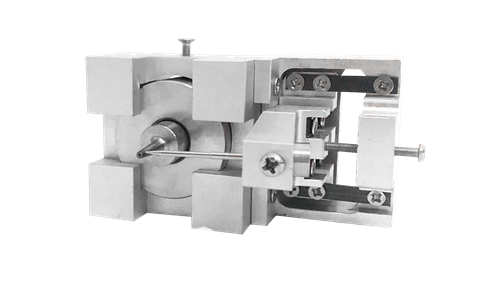

The company has been committed to the research and development of various ultrasonic equipment for more than ten years. Zeng-S, CENG-M and CENG-L developed by our company are basic and programmable micro-material spraying systems. Various types of catalyst suspensions, including carbon black ink, PTFE binder, ceramic slurry, platinum and other precious metals can be sprayed by this desktop ultrasonic spraying system, which can program and control x, y, z Three-axis coordinated operation, deposited on PEM fuel cells, GDL, electrodes, electrolyte membranes and solid oxide fuel cells to create maximum load and high battery efficiency. Compared with the precise and controllable liquid supply system, different types of customized nozzles greatly reduce the amount of material and produce highly uniform and durable, repeatable and durable paint production from R&D to medium batches. Small body, easy placement and stable spraying performance , Easy to operate.