Application Prospects of Ultrasonic Spray Heparin Coating

Ultrasonic spray heparin coating has broad application prospects, which are mainly reflected in the following aspects:

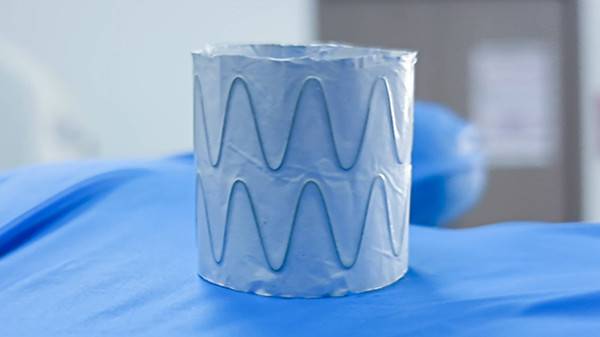

1. Cardiovascular field: stent surface coating: In cardiovascular interventional treatment, stent implantation is a common treatment method. Covering the stent surface with heparin coating by ultrasonic spraying can effectively reduce the risk of thrombosis after stent implantation, improve the success rate of surgery and the prognosis of patients. With the increasing incidence of cardiovascular diseases and the increasing requirements for treatment effects, the demand for heparin-coated stents will continue to grow.

- Artificial blood vessels and vascular graft coatings: For some patients who need vascular transplantation or use artificial blood vessels, heparin coating can improve the biocompatibility of blood vessels, reduce blood coagulation and thrombosis, and help maintain the patency of blood vessels. Ultrasonic spraying technology can evenly coat heparin on the surface of artificial blood vessels or vascular grafts, providing better treatment options for such patients.

2. Blood purification field: dialyzer and filter coating: During hemodialysis and blood filtration, the contact between blood and dialyzer or filter will trigger a coagulation reaction. Heparin coating can inhibit the coagulation process, improve the service life and dialysis effect of dialyzers and filters. Ultrasonic spraying technology can accurately control the thickness and uniformity of heparin coating to ensure the stable performance of dialyzers and filters.

- Plasma separation device coating: During the plasma separation process, heparin coating can prevent blood from coagulating in the separation device and improve the separation efficiency and quality of plasma. Ultrasonic sprayed heparin coating can provide reliable anticoagulation protection for plasma separation devices and meet clinical needs for plasma separation.

3. In vitro diagnostic field: Diagnostic reagent coating: In some in vitro diagnostic reagents, such as coagulation detection reagents, platelet function detection reagents, etc., heparin coating can prevent unnecessary coagulation reactions between reagents and blood, ensuring the accuracy of test results. Ultrasonic spraying technology can evenly coat heparin on the reagent carrier to improve the performance and stability of the reagent.

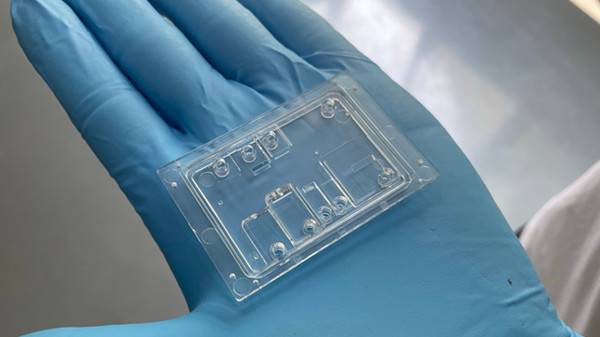

- Microfluidic chip coating: Microfluidic chip is a new type of in vitro diagnostic technology with narrow internal channels and blood easily coagulated. Heparin coating can maintain the blood fluidity inside the microfluidic chip and improve the efficiency and accuracy of detection. Ultrasonic spraying technology can accurately coat heparin coatings on the tiny channels of microfluidic chips, providing technical support for the application of microfluidic chips.

4. Other medical device fields: Catheter and guidewire coatings: Catheters and guidewires used in various interventional treatments, surface coating with heparin can reduce friction and damage with the blood vessel wall and reduce the risk of thrombosis. Ultrasonic spraying technology can achieve uniform coating on the surface of catheters and guidewires, improving their safety and effectiveness.

- Implantable sensor coating: Some implantable sensors need to be in contact with human tissue and blood for a long time. Heparin coating can improve the biocompatibility of sensors and reduce inflammatory response and tissue damage. Ultrasonic spraying heparin coating can provide stable anticoagulation protection for implantable sensors and ensure the normal operation of sensors.

5. Tissue engineering field: Tissue engineering vascular coating: In the process of constructing tissue engineering blood vessels, heparin coating can promote the growth and proliferation of vascular endothelial cells and improve the patency and biological function of blood vessels. Ultrasonic spraying technology can evenly coat heparin on the surface of tissue engineering blood vessels, providing technical support for the construction of tissue engineering blood vessels.

- Bioscaffold coating: Bioscaffold is a new type of material used for tissue repair and regeneration. Heparin coating can improve the biocompatibility and blood compatibility of bioscaffolds and promote cell adhesion and growth. Ultrasonic sprayed heparin coating can provide better performance and effect for the application of bioscaffolds.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions