In-depth Interpretation of the Electrolysis Experiment of Water

As a classic experiment in the field of chemistry, the electrolysis experiment of water plays an extremely critical role in helping us to deeply understand the composition of water and the principle of electrolysis. Next, let us explore this mysterious experiment in a comprehensive and detailed manner.

Purpose of the experiment

This experiment aims to prove conclusively that water is composed of hydrogen and oxygen through the process of electrolysis of water. At the same time, let us have a deep understanding of the basic principles and specific processes behind the electrolysis reaction, intuitively observe the phenomena presented during the electrode reaction, and accurately judge the properties of the generated gas. Through such experimental exploration, a solid foundation is laid for the subsequent in-depth learning of chemical knowledge.

Principle of the experiment

Water will undergo a decomposition reaction under the action of direct current, and the corresponding chemical equation is: 2H₂O = power on = 2H₂↑ + O₂↑. In the electrolytic cell, the cathode connected to the negative pole of the power supply undergoes a reduction reaction, at which time the hydrogen ions (H⁺) in the water gain electrons and generate hydrogen; while the anode connected to the positive pole of the power supply undergoes an oxidation reaction, and the hydroxide ions (OH⁻) in the water lose electrons and generate oxygen and water. It is this electron transfer process that realizes the conversion of water into hydrogen and oxygen.

Experimental device

- Power supply: A DC power supply is usually selected, such as a battery or a DC regulated power supply. The voltage is generally set at 6-12V to ensure that a stable DC power can be output to provide continuous and stable energy support for the electrolysis reaction.

- Electrolyzer: You can use professional electrolysis devices such as Hofmann electrolyzers, or you can make a simple electrolyzer yourself. If you choose to make your own, containers such as U-tubes or larger beakers can come in handy.

- Electrode: Commonly used electrode materials are graphite rods or platinum sheets. Graphite electrodes have the characteristics of low cost, excellent conductivity and relatively stable chemical properties; although platinum electrodes have high catalytic activity and are not easily oxidized, their cost is relatively high. It should be noted that if metal electrodes (such as iron, copper, etc.) are used, the electrode itself may undergo oxidation reaction at the anode, thereby interfering with the accuracy of the experimental results.

- Electrolyte: Generally, dilute sulfuric acid (H₂SO₄) or sodium hydroxide (NaOH) solution is used. Taking dilute sulfuric acid as an example, sulfuric acid will be completely ionized in water to produce hydrogen ions (H⁺) and sulfate ions (SO₄²⁻), which greatly enhances the conductivity of the solution and creates favorable conditions for the smooth development of the electrolysis reaction. Similarly, sodium ions (Na⁺) and hydroxide ions (OH⁻) ionized from sodium hydroxide solution can also play a similar role. However, the concentration of the electrolyte must be controlled well, as excessive concentration may cause danger.

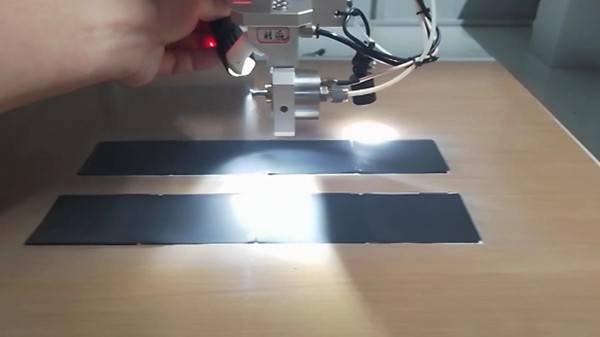

Application and advantages of ultrasonic spraying in electrolytic water

In the field of electrolytic water, Cheersonic ultrasonic spraying technology has shown unique value. Traditional electrode preparation methods have problems such as uneven coating, while ultrasonic spraying technology can spray the catalyst solution evenly on the electrode surface. This not only improves the uniformity of the active site distribution of the electrode, but also accurately controls the coating thickness, effectively improving the efficiency of water electrolysis. The electrode prepared using Cheersonic ultrasonic spraying technology can more efficiently promote the reaction of hydrogen ions and hydroxide ions during the electrolysis process, reduce the overpotential of the reaction, and significantly increase the production rate of hydrogen and oxygen. At the same time, the uniform coating also enhances the stability of the electrode, prolongs the service life of the electrode, and provides more reliable technical support for large-scale water electrolysis applications.

Experimental steps

- Preparation: First, carefully check the airtightness of the device to ensure that there is no leakage in the entire system, and confirm that the electrode connection is correct. Then, slowly inject an appropriate amount of electrolyte (such as dilute sulfuric acid or sodium hydroxide solution) into the electrolytic cell, making sure that the electrode can be completely immersed in the electrolyte.

- Turn on the power supply: Correctly connect the DC power supply to the electrode of the electrolytic cell, then turn on the power supply, and the electrolysis reaction will begin. At this time, it can be clearly observed that bubbles are continuously generated on the surface of the electrode, and there is a significant difference in the rate of bubble generation between the two electrodes. The cathode connected to the negative pole of the power supply generates bubbles faster, while the anode connected to the positive pole of the power supply generates bubbles relatively slowly.

- Collecting gas: The generated gas is collected by drainage method. A small test tube or gas collecting bottle filled with water is inverted on the two electrodes. As the gas continues to be generated, the water in the small test tube or gas collecting bottle will gradually be discharged. When a certain amount of gas is collected, quickly cover the mouth of the gas collecting bottle with a glass sheet under water, and then carefully remove it from the electrolytic cell.

Experimental phenomenon and analysis

- Cathode phenomenon: The volume of gas collected at the cathode is about twice the volume of the anode gas. When the gas collected at the cathode is tested with a lit wooden stick, it will be found that the gas can burn and produce a light blue flame, which proves that the gas is hydrogen. This phenomenon is completely consistent with the chemical equation for electrolysis of water. According to the equation, the volume ratio of hydrogen to oxygen is exactly 2:1.

- Anode phenomenon: The gas collected at the anode can reignite the wood with sparks, which fully proves that the gas is oxygen. The reason is that at the anode, the hydroxide ion (OH⁻) loses electrons to generate oxygen and water.

Experimental precautions

- Safety issues: When using a DC power supply, you must be highly vigilant to prevent electric shock accidents. If dilute sulfuric acid is used as an electrolyte, be sure to avoid sulfuric acid splashing on the skin and clothing. Once accidentally contacted, rinse with plenty of water immediately. Similarly, if sodium hydroxide solution is used, pay special attention to its corrosiveness.

- Experimental condition control: Always keep the electrode clean to prevent the electrode surface from being covered with oil or impurities to avoid affecting the electrolysis effect. The concentration of the electrolyte must be strictly controlled within an appropriate range. Too high or too low may have an adverse effect on the experimental results, or even cause the experiment to fail. In addition, during the experiment, ensure that the power supply voltage is stable to avoid voltage fluctuations interfering with the normal progress of the experiment.

Through the water electrolysis experiment, we can not only intuitively understand the composition of water and the principles of electrolysis reactions, but also with the application of cutting-edge technologies such as Cheersonic ultrasonic spraying technology in the field of water electrolysis, we are constantly expanding the boundaries of our understanding of this basic experiment, opening up new paths for more efficient and sustainable energy development and utilization in the future.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions