Customized Swiss Roll Slicing Solution

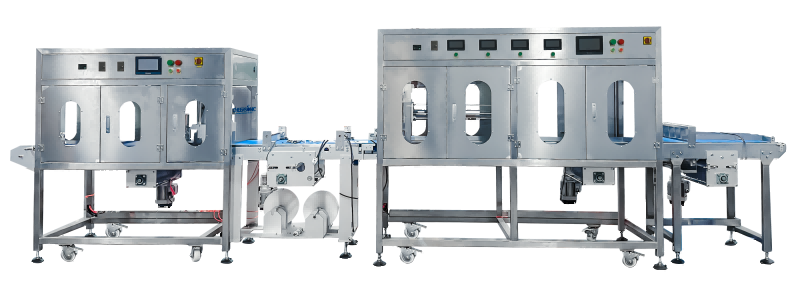

Step into the realm of superior manufacturing efficiency with our Customized Swiss Roll Slicing Solution – a marvel of modern engineering meticulously crafted to streamline your production process. This machine is specifically designed to cater to a variety of Swiss roll products, slicing them into uniform slices with exceptional precision and speed. Capable of handling volumes ranging from one to ten loaves simultaneously based on the product’s width, it showcases the ultimate versatility required in today’s dynamic food processing environments.

The core of this system revolves around a servo-driven conveyor belt, engineered for optimal throughput. Integrated with a servo blade actuator, it ensures that each slice is executed with pinpoint accuracy, regardless of the volume being processed. This feature is complemented by an ultrasonic cutting system, renowned for its effectiveness in tackling sticky or delicate products without compromise. The high-frequency vibrations of the blade produce clean, fray-free cuts, maintaining the integrity and visual appeal of the Swiss rolls.

Safety is paramount in any industrial environment, and our machine incorporates interlocked safety guards as a standard feature. These guards protect operators from accidental contact with moving parts, fostering a secure workplace culture while complying with stringent health and safety regulations.

Designed with hygiene in mind, the entire unit supports wash-down protocols for ease of cleaning and sanitation. Quick-release components and accessible surfaces facilitate regular deep cleans, ensuring compliance with strict food safety standards and prolonging the lifespan of your equipment.

To further enhance operational efficiency, we offer optional add-ons such as an auto-load conveyor for inbound product transport and an automated exit conveyor for post-processing offloading. These integrated solutions significantly reduce labor costs and increase throughput, making the entire process seamless from start to finish. By automating onload and offload stages, you can maximize your production line’s potential, allowing for consistent, high-quality output with minimal interruption.

In essence, our Custom Swiss Roll Slicing Solution represents the fusion of innovation and practicality, tailored to meet the specific demands of Swiss roll manufacturers. Experience unparalleled precision, hygiene, and productivity as you transform your production line into a paragon of efficiency. Embrace the future of food processing with confidence, knowing that every slice bears the mark of excellence, courtesy of our custom-designed machine.

About Cheersonic

Cheersonic manufactures the leading portioning equipment for bakeries producing fresh and frozen desserts. Since 1998 bakers have used Cheersonic machines to cut, slice and portion cheesecake, pie, layer cake, loaves, butter, cheese, pizza, sandwichs, and more. Cheersonic offers ultrasonic cutting solutions that support start-up bakeries and high production commercial facilities alike. Small standalone machines can be used in manual baking facilities and large inline robotic solutions aid in high speed production.

Cheersonic offers many ultrasonic slicing models, both inline and offline applications, with production speeds of 80 to 1,500 cakes or pies per hour.

Cheersonic’ latest offline introductions include ultrasonic cutting with or without divider inserts between each slice. This improves the quality of the cut and makes for a much better product presentation for the customer. In addition, robotic arm improves the speed, efficiency, and accuracy of the cutting process, producing professional looking products every time.

Chinese Website: Cheersonic Provides Professional Ultrasonic Cutting Solutions