Slicing of Swiss Roll

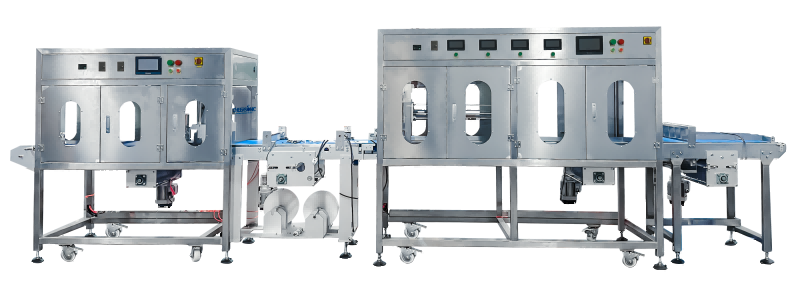

This custom-engineered machine is meticulously designed for the continuous supply and precise slicing of Swiss roll products. With its adaptable configuration, the machine can automatically slice anywhere from one to ten loaves side by side, depending on the width of the product. This flexibility ensures that it can cater to varying production needs with ease.

The machine incorporates a sophisticated servo-driven conveyor belt system that facilitates seamless movement of products through the cutting process. This system ensures precision and consistency in every slice. Additionally, the servo blade actuator enhances control and accuracy during the cutting operation, ensuring clean and uniform slices.

For sticky or delicate products, the machine can be equipped with an ultrasonic cutting system. This advanced technology allows for precise cuts without damaging the texture or integrity of the product, making it ideal for Swiss rolls and similar baked goods.

Safety is a paramount concern, and the machine is designed with interlocked safety guards to protect operators during operation. These guards are strategically placed to prevent any accidental contact with moving parts while still allowing clear visibility and access for maintenance.

To further streamline the production process, the machine features automatic product offload capabilities. Once sliced, the product is automatically transferred to the designated area, reducing manual handling and increasing efficiency.

Cleaning and sanitation are crucial in food production environments, and this machine is designed with these needs in mind. It is equipped with a “wash down” feature, making it easy to clean and maintain high standards of hygiene. The surfaces are smooth and accessible, ensuring thorough cleaning after each use.

For enhanced productivity, the machine can be integrated with an auto load conveyor for seamless onload of products into the cutting area. Similarly, an automated exit conveyor can be used to efficiently transport the sliced product away from the machine, completing the automation loop and minimizing manual intervention.

In summary, this custom machine is a state-of-the-art solution for the precise and efficient slicing of Swiss roll products. Its advanced features, including servo-driven conveyors, ultrasonic cutting systems, and comprehensive safety measures, make it an invaluable asset for any bakery or food production facility seeking to optimize their operations.

About Cheersonic

Cheersonic manufactures the leading portioning equipment for bakeries producing fresh and frozen desserts. Since 1998 bakers have used Cheersonic machines to cut, slice and portion cheesecake, pie, layer cake, loaves, butter, cheese, pizza, sandwichs, and more. Cheersonic offers ultrasonic cutting solutions that support start-up bakeries and high production commercial facilities alike. Small standalone machines can be used in manual baking facilities and large inline robotic solutions aid in high speed production.

Cheersonic offers many ultrasonic slicing models, both inline and offline applications, with production speeds of 80 to 1,500 cakes or pies per hour.

Cheersonic’ latest offline introductions include ultrasonic cutting with or without divider inserts between each slice. This improves the quality of the cut and makes for a much better product presentation for the customer. In addition, robotic arm improves the speed, efficiency, and accuracy of the cutting process, producing professional looking products every time.

Chinese Website: Cheersonic Provides Professional Ultrasonic Cutting Solutions