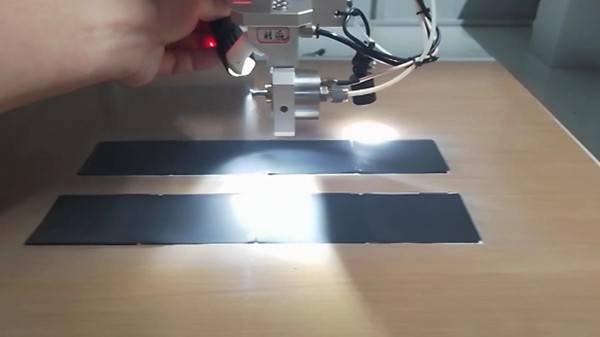

Ultrasonic Spraying Carbon Felt Coating

In the vast field of modern industry, ultrasonic spraying machines are emerging in the process of carbon felt spraying with their unique advantages.

1. Principle and characteristics of ultrasonic spraying machine

Ultrasonic spraying machine is an advanced equipment designed based on ultrasonic atomization technology. It uses high-frequency vibration to break up liquid paint into tiny droplets, and the particle size of these droplets can be precisely controlled within a very small range. This atomization method has significant characteristics compared with traditional spraying methods. First, it produces a very uniform droplet distribution, which is crucial for a material like carbon felt with its special microstructure and performance requirements. Because the surface of carbon felt needs to be evenly covered by the coating to ensure its stability and consistency in subsequent applications. Secondly, the ultrasonic atomization process is relatively mild and will not cause physical damage to the fiber structure of the carbon felt. The fibers of carbon felt are often the key to its performance. If it is subjected to excessive impact during the spraying process, it may cause the fibers to break or deform, thus affecting the overall performance of the carbon felt. Ultrasonic spraying cleverly avoids this. question.

2. Characteristics and spraying requirements of carbon felt

Carbon felt is a porous material made of carbon fiber with a series of excellent properties such as low density, high specific surface area, good electrical conductivity and thermal conductivity. In many fields, such as aerospace, energy storage, etc., carbon felt has broad application prospects. However, in order to further expand its functionality, it is often necessary to coat its surface. For example, in some energy applications, a specific catalyst coating needs to be sprayed on the surface of the carbon felt to increase its activity in electrochemical reactions. In the aerospace field, it may be necessary to spray high-temperature-resistant and anti-oxidation coatings to protect the performance of carbon felt in extreme environments. These coatings must not only be firmly attached to the surface of the carbon felt, but also need to have uniform thickness and good quality, which places extremely high demands on the spraying process.

3. Key points of operation of ultrasonic spraying machine in carbon felt spraying

When using an ultrasonic sprayer to spray carbon felt, the paint must first be carefully prepared. The coating formulation needs to be customized to the specific application and performance requirements of the carbon felt. For example, the viscosity of the coating should be moderate. It should not be too viscous to make atomization difficult, nor too thin to form an effective coating on the carbon felt surface. During the spraying process, the distance between the nozzle and the carbon felt surface needs to be precisely controlled. If the distance is too close, the local coating of the carbon felt may be too thick, causing sagging; if the distance is too far, the droplets may evaporate or be unevenly dispersed before reaching the surface of the carbon felt, affecting the quality of the coating. At the same time, the spraying speed and scanning method also need to be set appropriately. Generally, a uniform scanning path is used to ensure that each area of the carbon felt can be fully and evenly sprayed, and the spraying speed must match the frequency of ultrasonic atomization and the supply speed of the paint.

4. Advantages and significance of ultrasonic spraying machine for carbon felt spraying

The advantages of ultrasonic spraying machines in carbon felt spraying are many. From a quality perspective, it can achieve high-quality coatings, meet the high-performance requirements of carbon felt in different fields, and increase the added value of carbon felt. In terms of production efficiency, its precise control capabilities can reduce rework and defective products and improve the efficiency of the entire production process. Moreover, this spraying method is relatively environmentally friendly, reducing paint waste and environmental pollution. This is of great significance for the carbon felt industry to develop in a green and sustainable direction. It not only provides strong support for the performance improvement of carbon felt in traditional fields, but also opens up new ways for the expansion and application of carbon felt in emerging fields, promoting the development and innovation of the entire related industry chain.

In short, the application of ultrasonic spraying machines in the field of carbon felt spraying is a technological innovation of great value, and it will play an increasingly important role in future industrial development.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions