Photoresist Coater Machines

Ultrasonic photoresist coater machines have emerged as a reliable and versatile solution for a wide range of applications that demand precise and uniform coatings of materials such as photoresist and polyimide films. These systems offer several advantages over traditional coating techniques like spin coating and conventional spray coating, particularly in terms of their ability to achieve consistent coatings with precise thickness control and the flexibility to coat a variety of shapes and sizes.

Advantages of Ultrasonic Spray Coating Systems

- Precision Thickness Control: Ultrasonic spray coating systems can accurately control the thickness of coatings from submicron levels up to over 100 microns. This level of precision is crucial in applications where the thickness of the coating directly impacts the performance of the final product.

- Uniform Coating: The ultrasonic spray process ensures that coatings are applied evenly and consistently across the entire surface, eliminating the risk of uneven distribution or pooling that can occur with other coating methods.

- Flexibility in Shape and Size: These systems are capable of coating any shape or size, making them ideal for complex geometries and non-planar surfaces. This flexibility allows manufacturers to coat a wide range of substrates without the need for specialized fixtures or adaptors.

- Reduced Waste and Consumption: Ultrasonic spray coating systems typically use less material than other coating methods, as the ultrasonic energy promotes efficient atomization and transfer of the coating material. This results in reduced waste and lower material costs.

- Environmentally Friendly: Many ultrasonic spray coating systems are designed to be environmentally friendly, using low-VOC or VOC-free materials and minimizing waste and emissions.

- Improved Process Control: Advanced ultrasonic spray coating systems often incorporate automated controls and monitoring capabilities, allowing for precise process control and improved reproducibility.

Applications

Ultrasonic spray coating systems are widely used in a variety of industries, including:

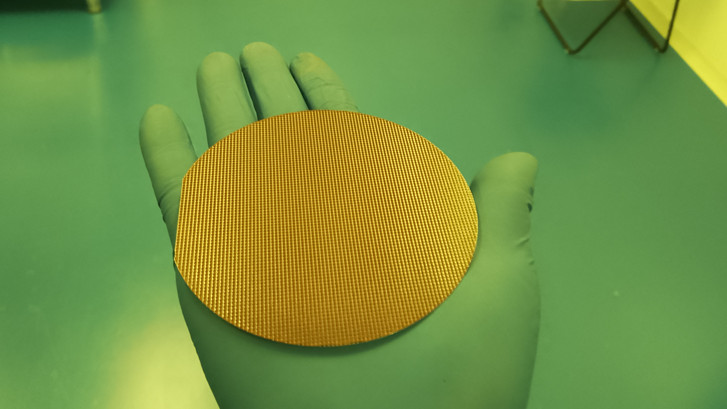

- Semiconductor Manufacturing: For the deposition of photoresist and other critical layers in the fabrication of integrated circuits.

- Microelectronics: For the coating of sensors, actuators, and other microdevices.

- Medical Devices: For the application of biocompatible coatings on medical implants and instruments.

- Flexible Electronics: For the production of flexible displays, sensors, and other devices that require conformal coatings.

- Aerospace and Defense: For the coating of precision components and systems with specialized materials.

In summary, ultrasonic spray coating systems offer a combination of precision, flexibility, and cost-effectiveness that makes them an attractive alternative to traditional coating methods. Their ability to deliver uniform, repeatable coatings across a wide range of shapes, sizes, and materials makes them a valuable tool for manufacturers in a variety of industries.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

Our coating solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Chinese Website: Cheersonic Provides Professional Coating Solutions