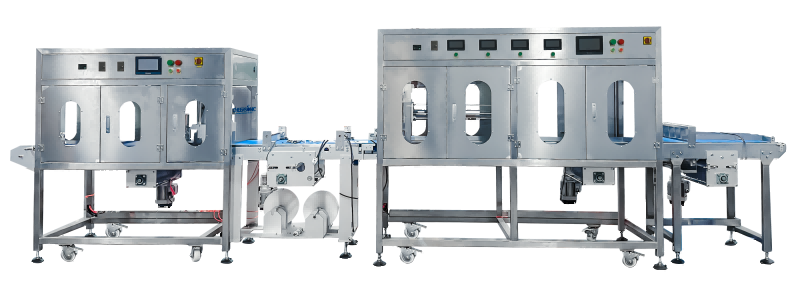

Cake Roll Cutting and Wrapping Machine

Cake roll cutting and wrapping machine is a machine specially used for cutting and wrapping cake rolls. This type of machine combines the functions of cutting and wrapping, which improves the efficiency and standardization of cake roll production. The following is a detailed introduction to the cake roll machine:

1. Functional features

- Cutting function:

The cake roll machine is equipped with a precise cutting system, which can cut according to the set size and shape to ensure that the size of each cake roll is consistent.

There are various cutting methods, including straight cutting, curve cutting, etc., to meet the needs of cake rolls of different shapes. - Paper wrapping function:

After cutting, the machine will automatically wrap the cake roll in paper or film to protect the cake roll from contamination and deformation.

The wrapping process is fast and accurate, which improves packaging efficiency and reduces the tediousness of manual operation. - High degree of automation:

Cake roll machines usually have a high degree of automation, which can realize full-process automated operation from cutting to packaging.

Reduces manual intervention, reduces labor intensity, and improves production efficiency and product quality.

2. Applicable scenarios

Cake roll machines are suitable for various bakeries, food processing plants and other places where cake rolls need to be produced. It can help enterprises improve production efficiency, reduce production costs, and ensure product standardization and consistency.

3. Precautions

When choosing a cake roll machine, you need to consider factors such as the cutting accuracy, packaging effect, degree of automation, and after-sales service of the equipment.

During use, it is necessary to perform correct operation and maintenance in accordance with the operating manual to ensure the normal operation of the equipment and extend its service life.

Clean and disinfect the equipment regularly to ensure the hygiene and safety of food.

In summary, the cake roll cutting and wrapping machine is an efficient and convenient baking equipment that can help enterprises improve production efficiency and product quality. When selecting and using it, you need to pay attention to relevant matters to ensure the normal operation of the equipment and the hygiene and safety of the product.

About Cheersonic

Cheersonic manufactures the leading portioning equipment for bakeries producing fresh and frozen desserts. Since 1998 bakers have used Cheersonic machines to cut, slice and portion cheesecake, pie, layer cake, loaves, butter, cheese, pizza, sandwichs, and more. Cheersonic offers ultrasonic cutting solutions that support start-up bakeries and high production commercial facilities alike. Small standalone machines can be used in manual baking facilities and large inline robotic solutions aid in high speed production.

Cheersonic offers many ultrasonic slicing models, both inline and offline applications, with production speeds of 80 to 1,500 cakes or pies per hour.

Cheersonic’ latest offline introductions include ultrasonic cutting with or without divider inserts between each slice. This improves the quality of the cut and makes for a much better product presentation for the customer. In addition, robotic arm improves the speed, efficiency, and accuracy of the cutting process, producing professional looking products every time.

Chinese Website: Cheersonic Provides Professional Ultrasonic Cutting Solutions