Ultrasonic Atomizer Spray Nozzle Technology

Ultrasonic Atomizer Spray Nozzle Technology is a unique, environmentally-friendly, low velocity spray technology that creates micron thickness, very uniform protective and functional thin films with no clogging and very little overspray.

Medical Stent Thin Flim Coating System

Medical Stent Thin Film Coating System with specialized stent arbor. All system components are compatible with the typical solvents and polymers used in stent coating. For example: solvents THF, acetone, DMAC, toluene, chloroform; polymers: urethanes, polycarbonates, silicones, styrenes. Touch screen control with the user able to program all functions of the stent coating process. Stent length: <40mm (Extensible function: for peripheral stent: <280mm. Call or email for more information and pricing. Several options are available and customization.

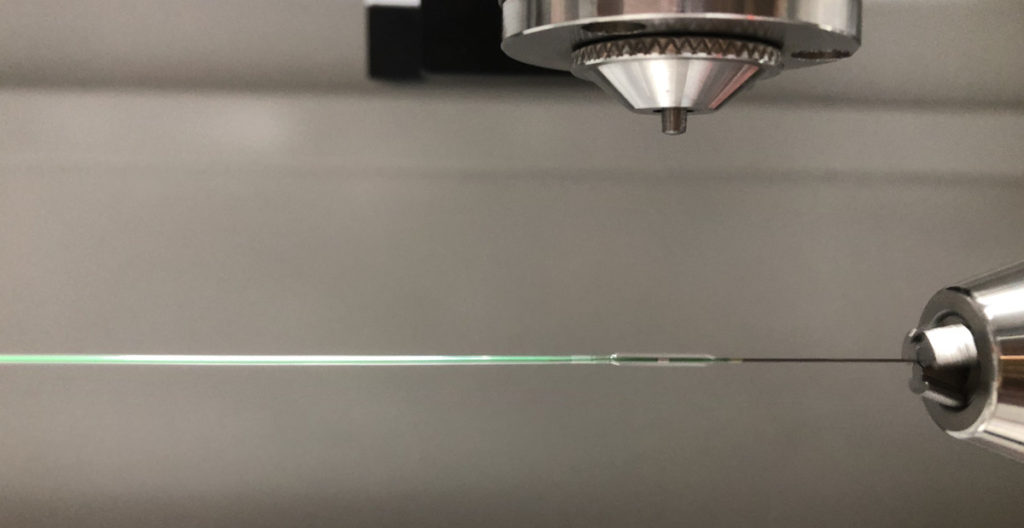

Balloon Catheter Thin Flim Coating Systems

Medical Balloon Catheter Coating System has mandrels for holding and keeping catheter straight, up to 2 meters long during the thin film coating process. Typical solvents THF, acetone, DMAC, toluene, chloroform; polymers: urethanes, polycarbonates, silicones, styrenes can be used with this system. Call or email for more information and pricing. Several options are available and customization.

Ultrasonic Thin Film Spray Coating System

Ultrasonic spray coating system includes XYZ motion system, Cheersonic ultrasonic spray nozzle, ultrasonic generator, constant liquid delivery system and air control. It is suitable for nano thin film coating e.g. solar cell, fuel cell, glass coating. Maximum spray area: 500mm x 500mm. Fully programmable with control of all functions for thin film coatings. Call or email for more information and pricing. Several options are available and customization.

Blood Collection Tube Coating System

Medical reagent coating machines are designed for high throughput production of Blood Collection Tubes (Venous & Capillary), Syringes, and Small Pharmaceutical Vials. The number and choice of nozzles are determined by the customer requirements in order to match their existing process fixtures and jigs, without compromising throughput and quality. We offer systems with either single part nozzles, or replaceable tip nozzles. Where applicable, we offer nozzles with additional features where heat sensitive reagents are used. Our unique liquid dosing pumps are designed specifically to work with and complement our nozzles for producing the highest level of precision and accuracy of the reagent delivery inside the Tubes, Syringes Barrels & Vials, for a total control of interior coating without overspray and contamination of the product, and work environment.