Project Description

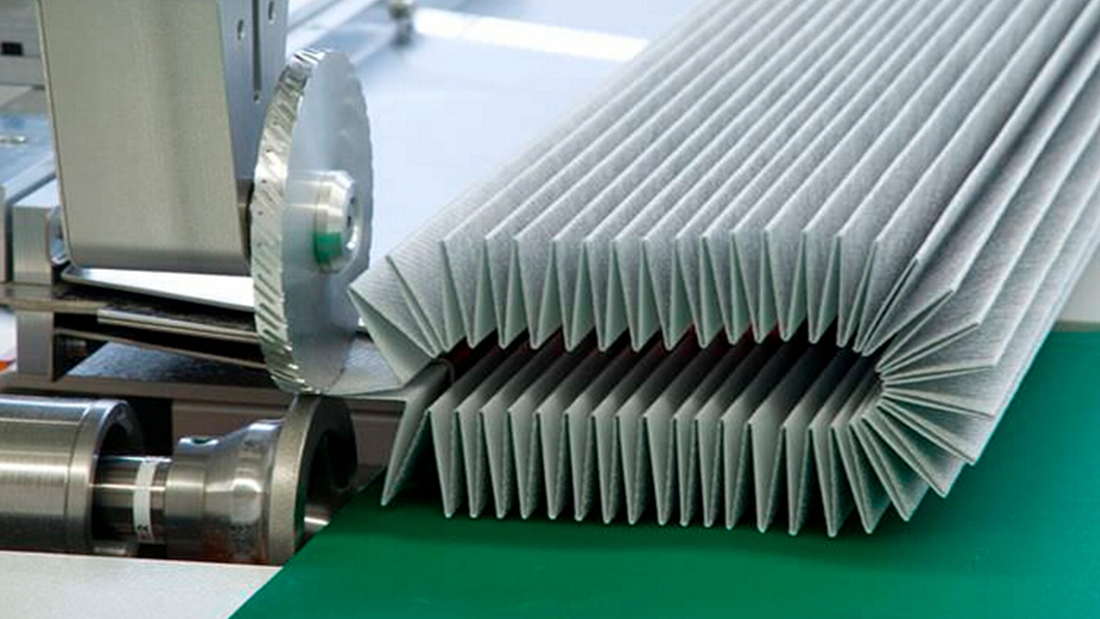

Ultrasonic Pleated Filters Welding

Product Description

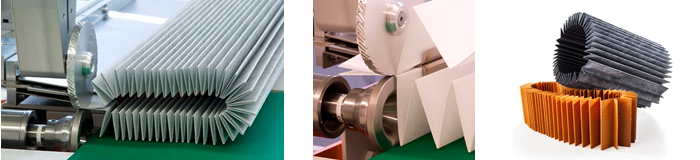

Continuous ultrasonic sewing machine for welding pleated filter elements in thermoplastic fabric or in cellulose with an adhesive film.

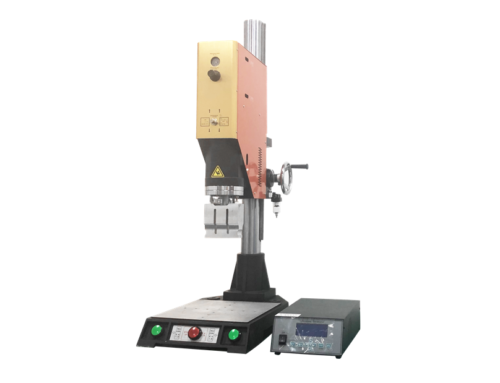

Ultrasonic pleated filters welding uses a ultrasonic sewing bonding system built by Cheersonic for clients that need to weld high quality pleated filters. The UWM550WS has been specially designed to weld pleated filter elements in thermoplastic fabric or weld pleated filter elements in cellulose or non synthetic fabric with an adhesive film.

This ultrasonic sewing system devised for pleated filters bonding is environmentally friendly because it does not require the use of any solvents nor adhesives. Ultrasonic welding with the UWM550WS eliminates the use of liquid glue. With a production speed faster than traditional gluing, the UWM550WS is highly cost-effective and provides a secure payback.

Show Details

Advantage

• Quick and efficient : works faster than traditional gluing

• Specially designed guide: easily adaptable for different pleat depths from 12 mm up to 60 mm and for different material thicknesses

• Also available as a modular unit for integration in production lines

• Provides a complete barrier seam

• Continuous machine requiring only one pass through

• Cuts and seals simultaneously, thus eliminating fraying or unravelling of bonded edges and seams

• Requires minimal operator training

| Ultrasonic Pleated Filters Welding Machine | |

| Machine Size | 2680x1670x1740 |

| Weight | 200kg approx. |

| Frequency | 35Khz |

| Power | 400Watt |

| Connection Voltage | single-phase 110 or 220 volt |

| Tuning | Automatic |

| Sealing Speed | 0.3 to 10m/min. option to 20m/min. |

| Seam Width | 1 to 10mm |

| Application | For pleated filter version |

| Compessed Air | Max 0.4MPa compressed air |

| Control System | User friendly touch screen |

| Operator Interface | Engineer functions include diagnostics, manual mode, password protection and system settings |