Project Description

Ultrasonic Nozzle for Coating Medical Appliance

Coatings can be applied to medical devices by dipping, spraying, vapor deposition, plasma polymerization and electrodeposition processes. Although these methods have been used to produce satisfactory coatings, they have many related potential drawbacks. For example, it may be difficult to obtain a uniform thickness coating on a single part or a batch of parts. In addition, many conventional methods require multiple coating steps or stages to apply a second coating material, or require drying between coating steps or after the final coating step.

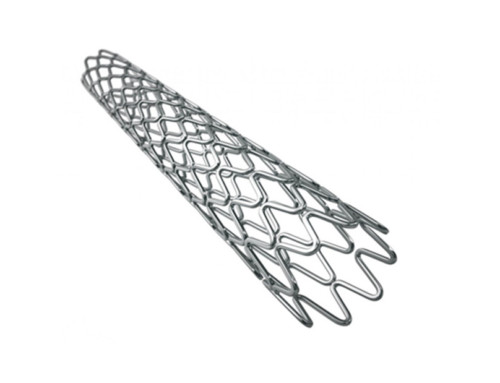

The stent is coated with an ultrasonic nozzle to atomize the coating while fluidizing the gas to suspend the medical device. The fluidizing gas can also transfer the atomized coating from the ultrasonic nozzle to the medical device.

By using an ultrasonic coating nozzle, no atomizing pressure is required. This eliminates highly focused jets and the subsequent high-speed shooting of the stent. There may be sufficient airflow in the fluidized stream to distribute the atomized coating and keep the stent fluid.

Recommended Equipment

Ultrasonic Atomization Nozzle

Laboratory Ultrasonic Coating System

Desktop Ultrasonic Spraying Machine

Desktop Ultrasonic Precision Spraying Machine

Medium Ultrasonic Spraying Machine

Ultrasonic Stent Coating System

Ultrasonic Balloon Coating Equipment

Inline Ultrasonic Coating System

UAL100 Ultrasonic Dispersion Syringe Pump

LULP500 Ultrasonic Laboratory Device

Prosonic1000 Industrial Ultrasonic Device

Prosonic3000 Most Powerful Ultrasonic Processor