Polymer Electrolyte Membrane Fuel Cells Coating System

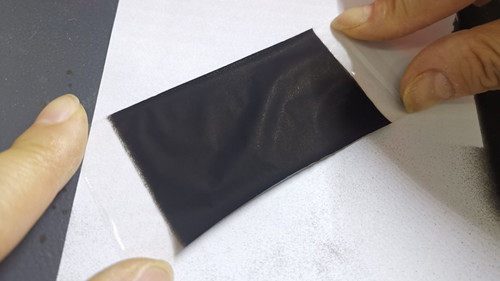

Bipolar plates are a major component of polymer electrolyte membrane fuel cells (PEMFCs). Bipolar plates play a multifunctional character within a PEMFC stack. It is one of the most costly and critical part of the fuel cell, and hence the development of efficient and cost-effective Bipolar plates is of much interest for the fabrication of next-generation PEMFCs in future. Ultrasonic spray is an ideal candidate to be utilized in Bipolar plates.

Applications of ultrasonic spray technology range from ordinary liquids to molten metal for air conditioning, drug delivery, combustion, textile coating, solar cell manufacturing, and lately fuel cell manufacturing. The major advantages of ultrasonic spray include uniform spray with narrow distribution of droplet sizes, controllable mean droplet size diameter by ultrasonic forcing frequency, low droplet velocity (soft spray) that minimize splashing and material waste, silent, low energy consumption (for atomization and spray shaping), and scalable.

Fuel Cell Catalyst Coating Systems Video

Recommended Equipment

Ultrasonic Atomization Nozzle

Laboratory Ultrasonic Coating System

UAM3000 Ultrasonic Medical Devices Spraying

UAM4000 Desktop Ultrasonic Spraying Equipment

UAM4000L Benchtop Ultrasonic Spray System

UAM6000 Ultrasonic Spraying Machine

UAL100 Ultrasonic Dispersion Syringe Pump

LULP500 Ultrasonic Laboratory Device

Prosonic1000 Industrial Ultrasonic Device

Prosonic3000 Most Powerful Ultrasonic Processor