Ultrasonic Atomization for Biopolymer Particles

Application of Ultrasonic Atomization for Biopolymer Particles and Tube Fabrication

This research aimed to study the potential use of ultrasonic atomization technique for biopolymer particles and tube preparation. Poly(lactic acid) was selected as a model polymer. The polymer solutions were, first prepared. For particles forming, the factors affecting the preparation such as the polymer concentrations, the distance between a nozzle and a target plates and the feed flowrate target plate were investigated. In case of tube fabrication, the feed flowrate and the time of atomizing were of interest. All samples were analyzed for particle sizes and SEM images.

For particles preparation, it was found that when increasing concentrations of Poly(lactic acid), the particles size of Poly(lactic acid) increased as a result of the increased viscosity of polymer solution, causing larger droplets of spray, hence large particles formed. Upon varying the distance between a nozzle and a target plate, it was found that the spray distance did not affect the particle sizes.

For tube fabrication, the polymer solution was atomized over the rotating shaft. The results showed the rotating shaft speed had no effects on the tube structure. The tubes could be successfully formed. The tube had rough surface without holes. When increasing the atomizing, the tube had rougher surface. To create porous structure of the tube, anti solvent was added to the polymer solution prior to spraying. The as-sprayed tube illustrated rough surface with network structures having porous-like scaffold structure due to the different evaporation rate between solvent and anti-solvent

Ultrasonic Spray Deposition Of Solar Cells Video

Recommended Equipment

Ultrasonic Atomization Nozzle

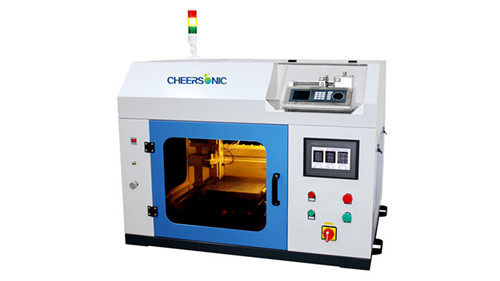

Laboratory Ultrasonic Coating System

UAM3000 Ultrasonic Medical Devices Spraying

UAM4000 Desktop Ultrasonic Spraying Equipment

UAM4000L Benchtop Ultrasonic Spray System

UAM6000 Ultrasonic Spraying Machine

UAL100 Ultrasonic Dispersion Syringe Pump

LULP500 Ultrasonic Laboratory Device

Prosonic1000 Industrial Ultrasonic Device

Prosonic3000 Most Powerful Ultrasonic Processor