Project Description

Direct Formic Acid Fuel Cell Spray

Direct Formic Acid Fuel Cell Spray. Performance of a direct formic acid fuel cell fabricated by ultrasonic spraying.

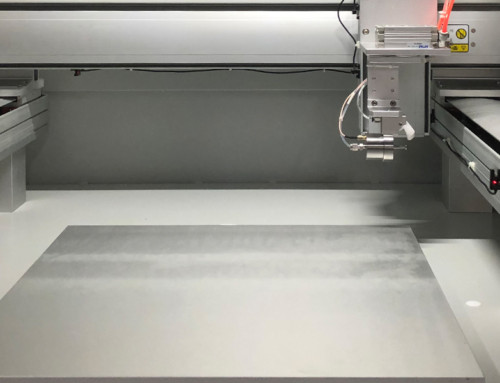

The performances of a direct formic acid fuel cells (DFAFCs) comprising anode catalyst layers prepared via the following three different coating techniques are tested: direct paint, ultrasonic spraying on the diffusion layer, and ultrasonic spraying directly on the membrane.

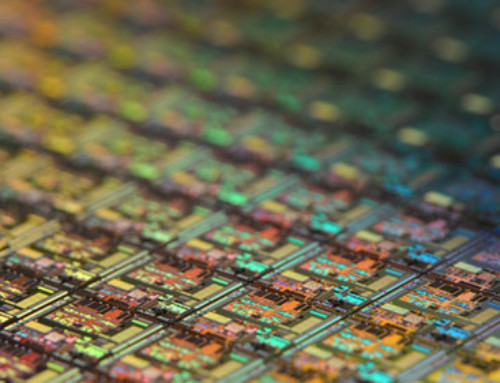

These tests confirm that the ultrasonic spraying is a suitable method for the fabricating DFAFC anodes. Palladium black was used for the anode catalyst and a commercially available Pt/C cathode electrode was used for all tests. Scanning electron microscopy revealed deep cracks caused by the porous substrate in the catalyst layers prepared by direct paint and by ultrasonic spraying on the diffusion layer. However, catalyst layers prepared by ultrasonic spraying directly on the membrane were less cracked and less porous, with small Pd particles.

The catalyst layer prepared by ultrasonic spraying directly on the membrane showed the highest electrochemical surface area among the three anodes. In performance tests, ultrasonic spraying on the membrane yielded the highest power output because it produces the lowest ohmic resistance, the lowest anode potential, and the highest electrochemical surface area. By coating the catalyst membrane directly with ultrasonic spraying, we prepared a DFAFC with maximum power density as high as 245 mW cm−2 using 5 M formic acid with 2 mg cm−2 of catalyst loading.

Proton Exchange Membrane Fuel Cell Spray Video

Recommended Equipment

Ultrasonic Atomization Nozzle

Laboratory Ultrasonic Coating System

UAM3000 Ultrasonic Medical Devices Spraying

UAM4000 Desktop Ultrasonic Spraying Equipment

UAM4000L Benchtop Ultrasonic Spray System

UAM6000 Ultrasonic Spraying Machine

UAL100 Ultrasonic Dispersion Syringe Pump

LULP500 Ultrasonic Laboratory Device

Prosonic1000 Industrial Ultrasonic Device

Prosonic3000 Most Powerful Ultrasonic Processor