Project Description

Ultrasonic Atomization Apray Energy Application

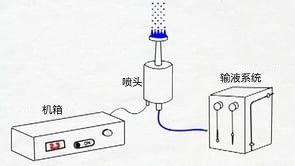

Ultrasonic Atomization Apray Energy Application. The principle of ultrasonic atomization: the ultrasonic chassis converts the mains into high-frequency electric energy. When the high-frequency electric energy reaches the transducer, it is converted into vibration mechanical energy of the same frequency by the transducer. The mechanical energy of the vibration breaks the liquid into UM-level droplets.

At present, the frequency of energy application is mainly 60KHZ.

Ultrasonic advantages:

1. Reduce waste

2. Atomization evenly

3. The coating thickness is controllable

4. Not easy to block

Energy application

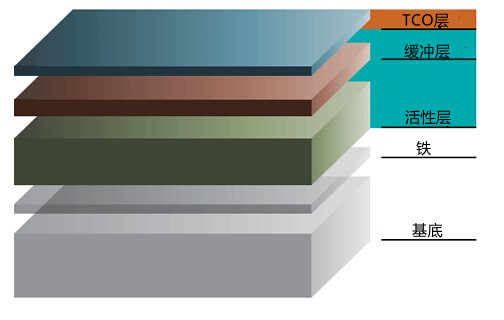

The first is the photovoltaic cell. Solar photovoltaic cells convert solar light energy directly into electricity. The main structure of photovoltaic cells: 1. Substrate 2 Iron 3. Active layer / buffer layer 4. TCO conductive coating

Ultrasonic is mainly responsible for spraying the active layer/buffer layer and the TCO layer.

Active layer / buffer layer Main substances: CIS, CIGS, CDTE, CZTS, DSC and other photovoltaic organic compounds. These photovoltaic compounds participate in the photovoltaic reaction.

Ultrasonic advantage: Each layer of these materials can be evenly coated. The ultrasonic wave has a better uniform effect than the high pressure spray.

TCO layer: The photovoltaic layer of the active layer/buffer layer does not have conductivity, and the TCO coating functions to collect current with its excellent conductivity.

Advantages of ultrasonic: TCO coating liquid is expensive, and traditional high pressure spraying will sputter. There is almost no sputtering of liquid during ultrasonic spraying, which effectively reduces the waste of liquid.

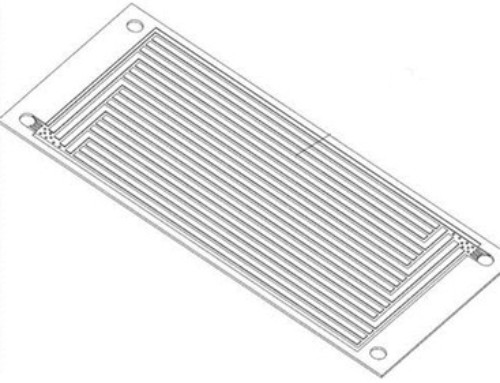

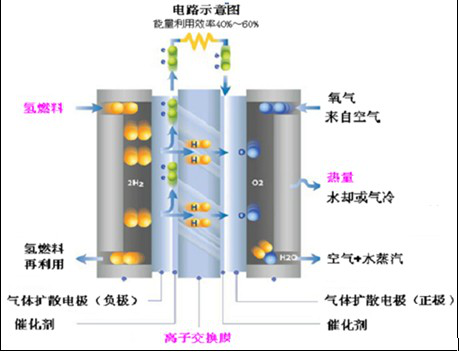

Followed by fuel cells. A fuel cell is a power generation device that converts chemical energy present in fuels and oxides into electrical energy. Ultrasonic is mainly responsible for spraying the PEM catalyst layer of the fuel cell and the GDL gas diffusion layer.

From the block diagram we can see that the catalyst layer is inside the gas diffusion layer.

PEM: PEM catalysts primarily accelerate the reaction of catalytic fuels and oxides. Its main content is platinum, which is a rare metal and a limited resource. The price is relatively expensive, and the current control fuel cell thickness is 20-37um.

GDL: The GDL gas diffusion layer mainly supports the catalyst layer and aeration drainage, and the thickness is required to be in the range of 100 um to 400 um.

Ultrasonic advantage: Compared with high pressure spraying, ultrasonic can control the thin layer thickness of the coating to make the coating thickness meet the standard requirements.

Ultrasonic Spray Video

Recommended Equipment

Ultrasonic Atomization Nozzle

Laboratory Ultrasonic Coating System

UAM3000 Ultrasonic Medical Devices Spraying

UAM4000 Desktop Ultrasonic Spraying Equipment

UAM4000L Benchtop Ultrasonic Spray System

UAM6000 Ultrasonic Spraying Machine

UAL100 Ultrasonic Dispersion Syringe Pump

LULP500 Ultrasonic Laboratory Device

Prosonic1000 Industrial Ultrasonic Device

Prosonic3000 Most Powerful Ultrasonic Processor