Project Description

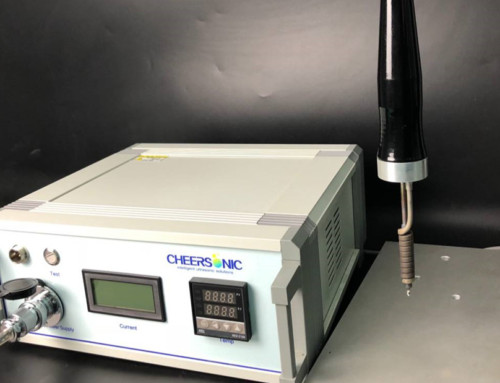

How Ultrasonic Atomizer Nozzles Work

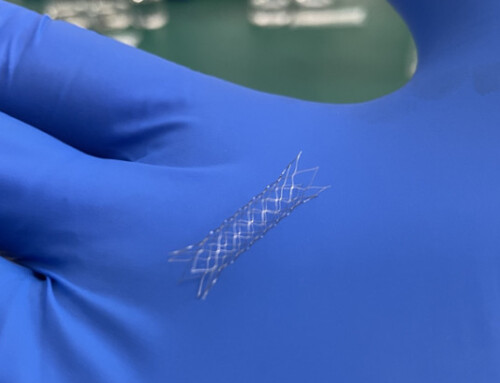

How Ultrasonic Atomizer Nozzles Work. The Cheersonic ultrasonic nozzle features a lightweight flow design that introduces liquid at the rear of the nozzle. Many different solutions can be made into a mist using nozzle materials made of titanium, stainless steel and fluoropolymer. Cheersonic ultrasonic nebulizers are easy to clean, maintain, reliable, and wear-free parts. Liquids of different viscosities are pumped through the center of the nozzle and atomized without the use of air pressure. The droplets are then used in coating, burning, moisturizing, making nanotubes or other applications requiring liquid droplets. Smaller and more uniform droplet sizes are a benefit of such liquid atomization.

At the center of the probe is a piezoceramic that converts electrical signals into mechanical vibrations. This vibration is amplified by the steps that form the tip of the probe and is reflected back toward the ceramic, mixing with the exiting waves to create a standing wave. These standing waves cause pumping to draw liquid toward the center of the probe.

The spray from these nebulizers will be smooth and controllable with little overspray. Spray thickness is nano-micron and can be adjusted by all users. The thickness is set by the delivery flow rate or spray, the power level of the nozzle, the liquid characteristics, and the time the substrate is exposed to the liquid. For heavy coatings, low frequency probes are used, and for ultra-thin coatings, higher frequency nozzles are typically used.

Ultrasonic Atomizer Nozzles Video

Recommended Equipment

Ultrasonic Atomization Nozzle

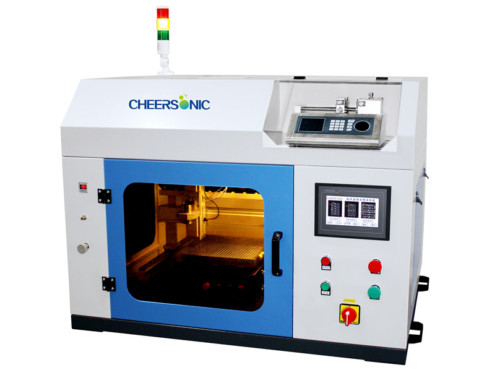

Laboratory Ultrasonic Coating System

UAM3000 Ultrasonic Medical Devices Spraying

UAM4000 Desktop Ultrasonic Spraying Equipment

UAM4000L Benchtop Ultrasonic Spray System

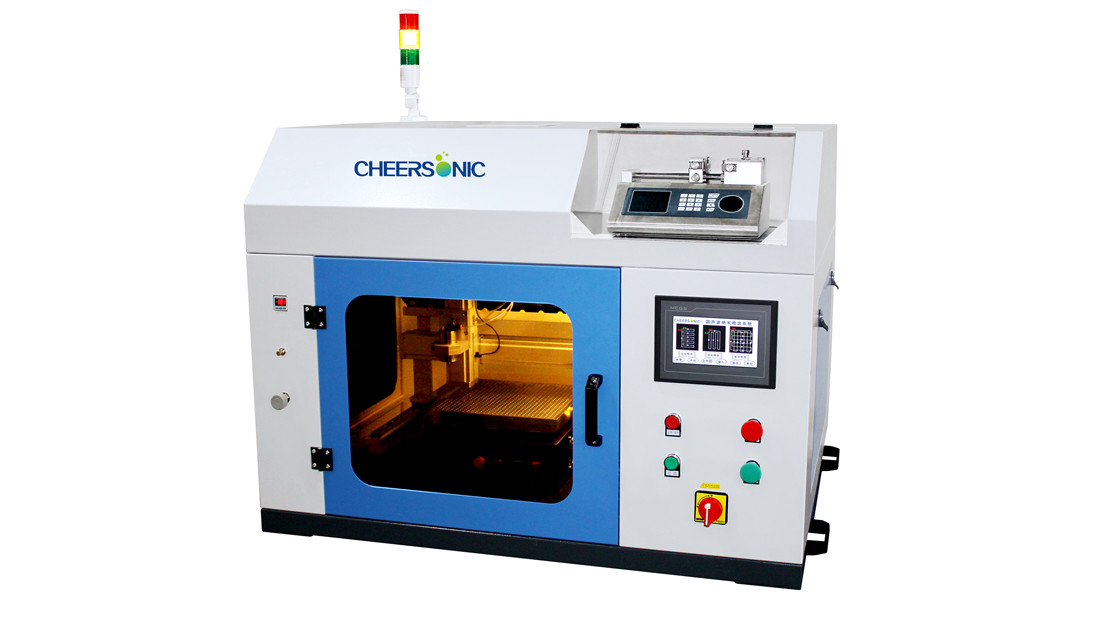

UAM6000 Ultrasonic Spraying Machine

UAL100 Ultrasonic Dispersion Syringe Pump

LULP500 Ultrasonic Laboratory Device

Prosonic1000 Industrial Ultrasonic Device

Prosonic3000 Most Powerful Ultrasonic Processor