Project Description

The Influence Factors Of Ultrasonic Spray

Ultrasonic spraying equipment application range is very wide, from involvement in medical equipment to solar cell production to the production of electronic equipment, everywhere reflected ultrasonic spraying equipment and spray pressure, rotating spray and so on the different and outstanding. But ultrasonic spraying equipment application range is so wide, and single from spray this action in terms of a lot of people will think that the ultrasonic spraying equipment seems to be universal, in fact, in the same field as is the use of ultrasonic spraying different, of course, these different users are unknown, these will be in the design process is perfect.

This article simply ultrasonic spraying equipment in different areas in the process of using a variety of influencing factors and the influence of each factor. From the ultrasonic spray utility to distinguish, focusing on two aspects: one is ultrasonic spraying atomized droplets of grain diameter, ultrasonic spray flow performance.

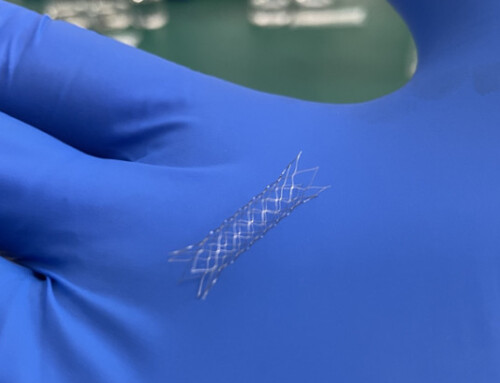

The key factors that affect the droplet size is ultrasonic vibration frequency of spraying equipment, the higher the frequency, droplets are also some small particle diameter, secondly by atomizing the liquid density and surface tension of liquid also has certain influence, but is generally not included in the scope. CHEERSONIC research and development of ultrasonic ultrasonic spraying equipment of spray droplets are soft, low velocity of spray, avoid the common phenomenon of excessive spraying pressure spraying.

The influence factors of traffic performance has four, respectively is atomized surface area, orifice size, vibration frequency and fluid properties. Orifice size decide the flow and the flow rate and imported into the atomized liquid velocity on below. When the liquid flow rate is too large, atomization surface will not be able to spray liquid, in general, low velocity on the surface of the atomization “attractive” enough to attach the liquid on the surface spray surface, thereby to atomization, but low liquid flow rate occurs accidentally atomization phenomenon. Atomization surface area is another factors influencing maximum flow, the amount of liquid atomization surface to withstand both while retain ability needed to produce atomization film has a limit, if the traffic is too big, will exceed atomization surface can keep the ability of liquid membrane, thus unable to atomization. Working frequency of atomized particles diameter image not only impact on the flow as well as, when the ultrasonic frequency, the greater the atomized particle diameter is smaller but the smaller the atomized flow then.

Ultrasonic spraying equipment in addition to the above reason itself, the nature of the liquid also has a great influence, first will handle liquid is divided into three categories, the first is the pure liquid, containing only a single component, such as water; The second type is a pure solution, such as physiological saline; The third kind is contain solid mixture, such as graphene solution. Pure liquid usually only consider the liquid viscosity, ultrasonic spraying equipment can handle liquid viscosity of 100 CPS biggest; Pure solution besides considering the liquid viscosity, but also exists in the liquid polymer, when the liquid atomization surface separation formed by the steric (ultrasonic atomization droplet, polymer molecules will hinder the formation of the discrete droplets; Contains solid mixture, mainly considering the solid content and solid particle size, solid particle diameter is far smaller than droplet diameter, or the result of atomization is solid-liquid separation, liquid solid content can not exceed 40%, other solid content is too big, will greatly increase the difficulty of atomization.

In a nutshell, supersonic spraying equipment main spraying effect of ultrasonic frequency, orifice size, spray surface area, vibration frequency and fluid properties.

Ultrasonic Atomizer Spraying Video

Standard Unit Spraying Solutions

Standard – Ultrasonic Nozzle

Standard – Ultrasonic Generators

Automatic-Production Spraying Solutions

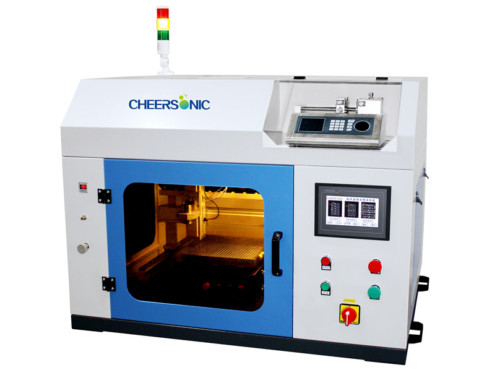

Flat Type Ultrasonic Spraying Machine

Automatic – UAM3000 Ultrasonic Spraying Machine

Automatic – UAM4000 Ultrasonic Spraying Machine

Inline Spraying Solutions

Inline Ultrasonic Spraying Machine