Project Description

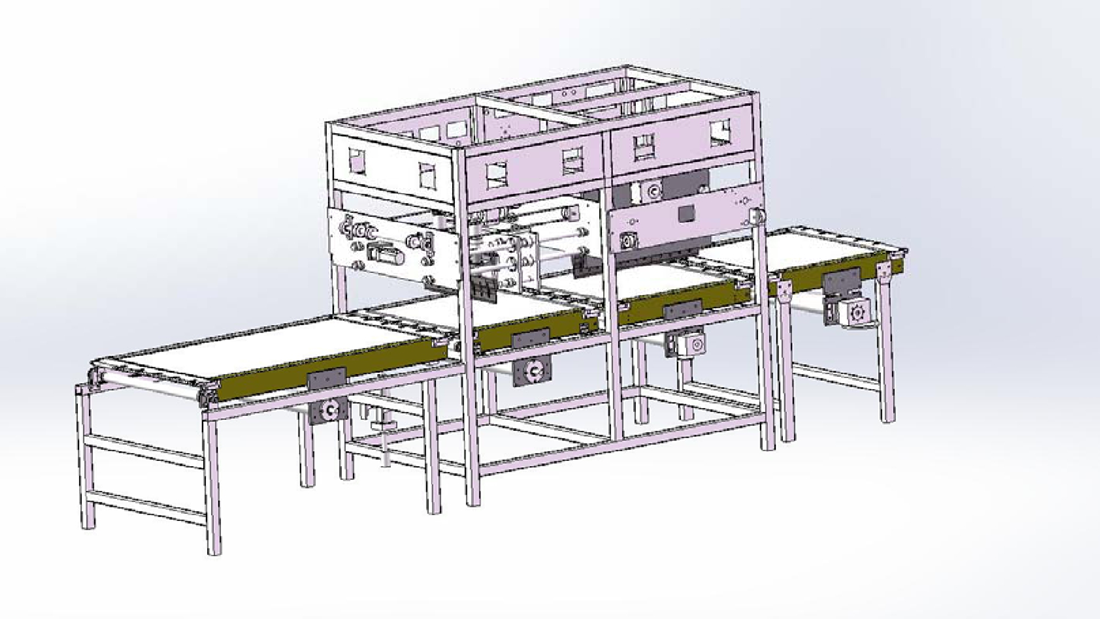

The UFM8100 dual-position ultrasonic food slicing system features line-up, multi-slice mode and high-efficiency features, dual station cutting jobs, slitting, cross cutting or dicing, along with a scrap reject system Remove the edge of the food scraps to the conveyor belt, to ensure food production efficiency and food production quality. After the equipment is started, the product first enters into longitudinal slitting area, carries on slitting and slitting is completed after the transverse cutting is completed, the two movements are respectively completed in a single station, slitting and cutting at the same time for different products to be cut. When the product is used by itself, the equipment is manually loaded, one-touch activated, automatic cutting, automatic discharging and artificial feeding. When used together with the food manufacturer’s existing pipeline, the equipment can be connected to an extruder or tunnel furnace, Machine, fully automated assembly line operations.

Feature

• Cutter speed adjustable in sections:

– When cutting down food, slowly down

– Up upward when leaving food

• Water chestnut clear, clean and tidy

• Dimensional accuracy: plus or minus 2mm

• The control system can be set to automatic mode, jog mode, easy to operate; password system protection

• After setting is completed, a key start, automatic cutting

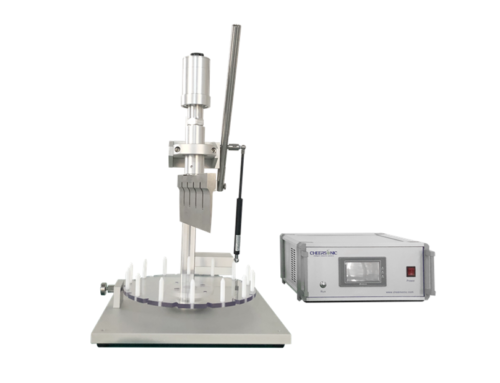

• Automatically chase ultrasonic drive power, real-time tracking of ultrasonic cutting knife frequency, to ensure that ultrasonic cutting knife work in a stable state, suitable for long hours of continuous work

• Horizontal and vertical cutting, two stations at the same time, cutting speed, increase production

• Ultrasonic transducer, horn, cutting knife, drive power all independent research and development, production, to ensure stable and reliable ultrasonic system operation

Application

The device has a variety of slitting modes: cut rectangle and slice mode. Working speed and angle parameters are adjustable. It is used to cut various shapes such as bread, cake, sugar and other foods in the shape of strips and rectangles. (Note: This device is suitable for cutting products length less than 810mm, width less than 560mm, greater than this length or width, it is recommended after cutting the ultrasonic cutting equipment.)

| UFM8100 Ultrasonic Food Slicing System | |

| Machine Size | 4000*1000*1800 |

| Weight | 800kg |

| Rated Power | 10kw |

| Voltage | 220v |

| Cutting Speed | 60 knives / minute |

| Maximum Cutting Size | The maximum width of 560mm*810mm |

| Maximum Effective Cutting Height | 60mm |

| Cutter Number | 5 |

| Cutter Size | 305mm*2 and 255mm*3 (other optional) |

| Is it rotatable? | No |

| Can Be Cut Type | Cut Slice |

| Conveyor | 1 |

| Rack Structure | 304 stainless steel rack |

| Security System | Security Door |

| Screen | 7-inch touch screen |

| Control Cabinet | Built-in |

| Control System | Six-axis Control System |

| Cutter Control System | Servo Motor |

| Compressed Air Connection | 40 psi; 3 kgf / cm² (for jigs only) |

| Products Into And Out Of Material | Conveyor automatically enters and exits the material |

| Machine Mobility | Casters |