Project Description

Tin Ultrasonic Soldering Iron

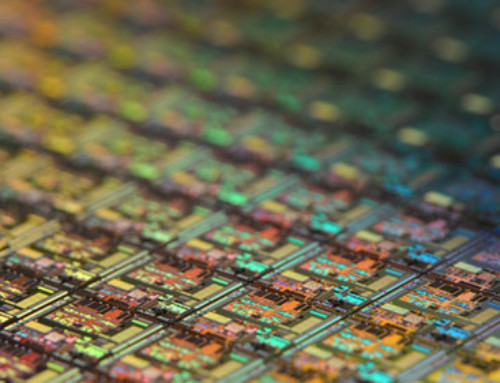

Tin

Tin is a malleable, ductile and highly crystalline silvery-white metal. When a bar of tin is bent, a crackling sound known as the tin cry can be heard due to the twinning of the crystals.In modern times, tin is used in many alloys, most notably tin/lead soft solders, which are typically 60% or more tin. Another large application for tin is corrosion-resistant tin plating of steel.

Tin Results

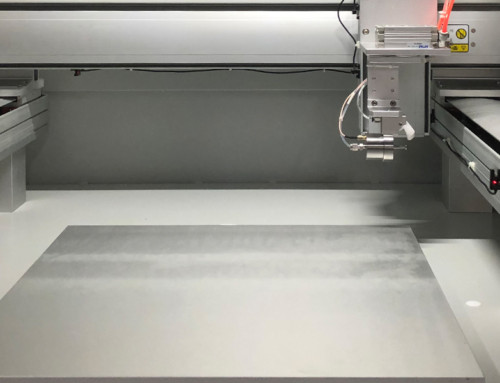

Ultrasonic soldering machine is a new ultrasonic bonding tool, ultrasonic vibration by soldering the solder surface of the article and firmly bonded, is widely used in glass, ceramics, crystal silicon devices (the LED, LCD, etc.), the accuracy of the welding of a superconducting material, packaging, and other electronic products between weld metal and nonmetal. No need to use when using flux (ultrasonic vibration of the tool head and the surface to remove any dirt or oxide layer), comprising: a high stability back to temperature quickly, without flux, does not produce harmful gases, effectively prevent the generation of bubbles and pinholes etc., to improve production efficiency, product quality and reliability.

The Effect of Ultrasonic Soldering Iron

CHEERSONIC developed ultrasonic soldering machine Features: ultrasonic removal of solder and the solder surface oil and base metal oxide to protect the metal surface to achieve the perfect cleanliness; increase the welding area, reducing the surface tension of the material to be welded; without any flux, does not appear harmful gases, welding protection of personal health workers; post-weld-free cleaning, eliminating the use of flux after soldering, electrical insulation performance degradation and short-circuit problems: internal pads without bubbles and pinholes generation, removal weld, false welding, improve the welding quality, guarantee yields and reduce welding time, improve work efficiency; pads smooth appearance, high joint strength, not aging, no external pressure stress, to prevent oxidation of the surface once again occurred during welding.