Project Description

Ultrasonic Soldering Iron for PCB

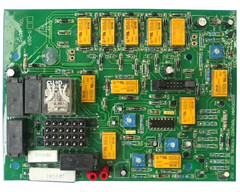

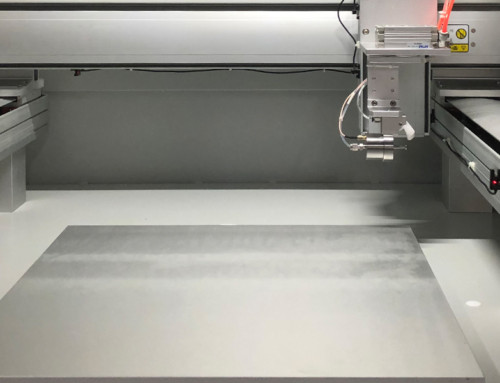

PCB

PCB, also known as printed circuit board, is an important electronic components, electronic components to support the body, is the carrier of electronic electrical connection. Since it is made of electronic printing, therefore is called “printed circuit board.

PCB Results

Ultrasonic soldering systems offer the advantage of the fluxless soldering of many metals in common use as well as previously difficult to solder materials such as aluminium, ceramics, glass and silicon’s used in microelectronic applications. The unit consists of the soldering iron itself, which is rated at 80W and can reach temperatures of up to 450°C, and is fitted with interchangeable screw in copper bits. The ultrasonic transducer is built into the soldering iron handle and the need to prevent this unit being overheated necessitates the continuous use of a cooling air supply.

The Effect of Ultrasonic Soldering Iron

Ultrasonic soldering iron is an intermediate layer to melt by the heat of welding materials, and polyethylene solution through ultrasonic cavitation bubbles generated in the liquid, forming a void-free seamless or welded. Ultrasonic welding does not require high temperature electric iron can be based on ultrasonic welding at a low temperature, low temperature welding stress relaxation in favor of leaving the stress decreases, to avoid weld cracking phenomenon.